Related Vendors

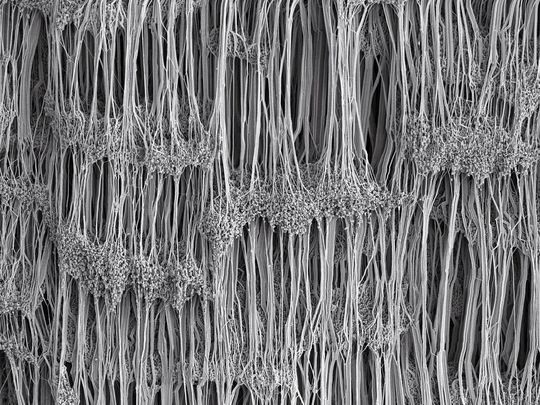

While such a structure changes the sealing properties (the transverse strength, for example), this can be taken into consideration structurally. Expansion allows for tapes to be produced that are flexible enough to be laid in even narrow radii.

The following properties are characteristic of gasket tapes made of ePTFE:

- Easy and fast adaptation to suit even complex flange geometries

- Design flexibility because of the various widths, which then allow for higher surface pressures (higher tightness classes)

- High creep resistance compared to other PTFE-based materials

- Excellent adaptability to flange irregularities

- Not reusable (due to the high compression and low spring back)

- Non-biodegradable, do not age, UV-resistant

- Resistant to all types of media (pH 0 to 14)

- Long shelf life, limited only by the declining bonding strength of the mounting aid adhesive tape.

Mounting of ePTFE Gasket Tapes

ePTFE gasket tapes are mounted on one of the flat sides of the tape using adhesive tape. The adhesive only serves as a mounting aid and has little or no impact on the sealing effect. The adhesive is also considerably less temperature- and chemical-resistant than ePTFE.

This means it usually decomposes during operation. This makes it easier to remove later on. When closing the seal made of an ePTFE gasket tape, one must make sure that the ends overlap and the right method is used. Basically, there are two different types of ePTFE gasket tape materials that require different overlapping methods: monoaxially and multiaxially ePTFE.

(ID:43333945)

:quality(80)/p7i.vogel.de/wcms/40/8f/408f074f8094bca2cd9bb078e79eccb0/0129580192v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/f3/4a/f34abcf99d71d8bff5a4e98b60889c8e/0129239597v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/5c/27/5c27bddaef122b61c636e31d82a33bd9/0129017834v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/f7/f0/f7f0fdf4a4e1d872d078d63abfa4a7fd/0127844838v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/0a/1c/0a1c5f661e1df4b35d4cd8e4901e4035/0129624833v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/9f/7f/9f7f9d5256b75ba8141a63bbf981b793/0129506442v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/ed/af/edaf3b0b2506f65f338232550b661eb3/0129281129v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/66/29/66293f3c9de08b472f095dc9602bcc7d/0129279548v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/d7/9e/d79e4ba6b9e0923d1513b843962712d9/0129591121v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/26/12/261210e5920899e5c35c4f905d3be8bd/0129399814v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/3e/e6/3ee6ff7ac2852491ce36fd6cb84bb7f0/0129534719v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/fc/42/fc420e2134a13a67212be7e5f68c63d6/0129419035v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/3c/09/3c090686df20769698f3203d11960151/0129534706v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/69/3c/693cd37dc03f7a3be3f6e40cdac3ccca/0129534194v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/69/08/6908c3bb3fba2484c5b541cb82c4e162/0129451354v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/d8/31/d831a92b2862f06b828503add415bd9a/0129449661v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/be/e1/bee13b8d51a419b9b8f0685e2b9d47bf/0128917673v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/51/7a/517a4e83c5827663b4839f5ddb98f434/0128872953v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/d5/72/d5728578b35b72f365f5086bc1d068da/0128662441v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/a9/69/a96920e47e362a9cf0b9916b7ad3d30a/0128071795v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/18/47/1847e6b1456c96f04bd511bbd21f3779/0129039479v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/3b/fd/3bfda4bbcb1a60004c330bde3b705109/0128453300v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/cc/19/cc19aa5fec6f6f2b25dbd9516efed735/0128077403v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/de/66/de66dd32e1af2fa37ff20bded4417afc/0127787418v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/6b/cc/6bcc3d26e1c7c74d90a10bc3ca296ae1/0128362351v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/24/c8/24c84ab6b1bcd24468a87820a07a85aa/0128194707v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/1d/3e/1d3e2788eb37c1e974f36337c8d33cb5/0128191010v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/19/76/1976928d7d0a2ed7c1eeba7ade8552c8/0126365603v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/0c/04/0c045977492b7af382831470a813c15f/0129625714v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/99/d2/99d2e5e83062b4cf2aa3dc0a60d15f23/0129624804v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/20/22/202266f978d422d655fa5909dfb54fd5/0129592446v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/98/f0/98f06d033c1aafbfe6b9b0e22abd0303/0129590496v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/f8/29/f8298429c1638b949a6f76346f6709c7/0118701710v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/07/24/07242664ab2b1c7841c9d9d0a127670c/0116045959.jpeg)

:quality(80)/p7i.vogel.de/wcms/c9/79/c979a20b32395ddfa93fe7ead90578a0/0108386061.jpeg)

:quality(80)/p7i.vogel.de/wcms/9e/5c/9e5c92d942ed046a27562d6e3d730c92/0103483548.jpeg)

:quality(80)/p7i.vogel.de/wcms/16/3d/163da381529db3a47348a9440655529b/0125732969v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/e7/82/e782bbbf96e4971c22241d76e5de1720/0124855387v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/f9/40/f940b2630f4805f08212fd851af46d6d/0124788233v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/3a/6d/3a6d046cf1db266c3009cecb2af8e2b7/0124656182v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/a8/4e/a84e8039a90a5cf4751d01ebcf6ba1a9/0127510172v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/17/c7/17c703445f134eb3d7ecc7918dda2762/0124596096v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/2a/2c/2a2cffc07f51019065387cd63241b5ce/0119463370v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/b1/7e/b17ea8c62ccafad1d1fb072d6199bbd6/0118578446.jpeg)

:quality(80)/p7i.vogel.de/wcms/d1/a8/d1a83b822e16733380268322d033abdc/0129239584v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/bb/54/bb54162539c6fc9ac135719af078ea06/0129188218v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/02/02/020250273eb250f46d355a16c1baeb74/0129163933v2.jpeg)

:fill(fff,0)/images.vogel.de/vogelonline/companyimg/107800/107832/65.jpg)

:fill(fff,0)/images.vogel.de/vogelonline/companyimg/2000/2093/65.jpg)

:fill(fff,0)/images.vogel.de/vogelonline/companyimg/101800/101879/65.jpg)

:quality(80)/p7i.vogel.de/wcms/b4/6f/b46f24c562a10a8c0c40b1f9c509ed45/0124276026v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/19/76/1976928d7d0a2ed7c1eeba7ade8552c8/0126365603v1.jpeg)