Related Vendors

Deformation takes place when equilibrium is reached. With a seal, this is a reduction in the thickness that reduces the bolt elongation and thus the preload. This ultimately means a loss of strength or surface pressure that depends on the stiffness of the sealing system with respect to its extent. This surface pressure loss is called “creep relaxation” and can be so great that the bolts are loosened completely.

Creep and the respective relaxation mainly occur during the heating up and cooling phases, in other words during thermal cycling. These effects occur to a significantly lower degree with a constant temperature. Creep relaxation is the main reason why simple PTFE (often brought into shape by sintering) can hardly be used in heat exchangers, which by their very nature are often subjected to significant temperature load changes.

Increasing the Creep Resistance Through Expansion

There are different ways to reduce the creep resistance of PTFE. One way is to add filler materials. This technique is only appropriate for use with gasket tapes to a limited extent due to the fact that the flexibility of filled PTFE is extremely limited.

Strips of simple PTFE are also not very useful for the same reason because it is difficult to form them into the required shape at the time of installation. Expanding the PTFE material offers an effective solution. This creates a microporous structure through mechanical stretching.

Conformability Through Compressibility

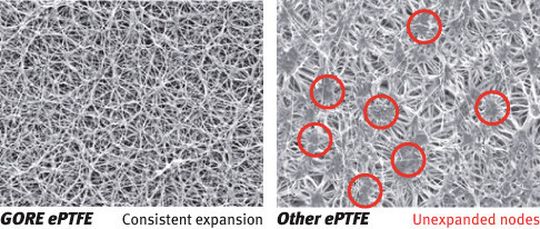

This structure causes a significant change in properties. On the one hand, it improves the conformability due to the higher compressibility as well as creep resistance on the other hand. Here, it is important for the expansion to take place as evenly as possible. This is crucial to ensuring that the sealing properties are and remain the same at all positions of the seal. It can still have a texture, however, although it should not extend throughout the entire seal (in other words for the entire length of a tape). In fact, a controlled transverse texture (with a circular transfer radially) can have a positive effect on deployability and bending stiffness.

(ID:43333945)

:quality(80)/p7i.vogel.de/wcms/40/8f/408f074f8094bca2cd9bb078e79eccb0/0129580192v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/f3/4a/f34abcf99d71d8bff5a4e98b60889c8e/0129239597v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/5c/27/5c27bddaef122b61c636e31d82a33bd9/0129017834v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/f7/f0/f7f0fdf4a4e1d872d078d63abfa4a7fd/0127844838v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/0a/1c/0a1c5f661e1df4b35d4cd8e4901e4035/0129624833v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/9f/7f/9f7f9d5256b75ba8141a63bbf981b793/0129506442v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/ed/af/edaf3b0b2506f65f338232550b661eb3/0129281129v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/66/29/66293f3c9de08b472f095dc9602bcc7d/0129279548v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/d7/9e/d79e4ba6b9e0923d1513b843962712d9/0129591121v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/26/12/261210e5920899e5c35c4f905d3be8bd/0129399814v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/3e/e6/3ee6ff7ac2852491ce36fd6cb84bb7f0/0129534719v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/fc/42/fc420e2134a13a67212be7e5f68c63d6/0129419035v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/3c/09/3c090686df20769698f3203d11960151/0129534706v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/69/3c/693cd37dc03f7a3be3f6e40cdac3ccca/0129534194v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/69/08/6908c3bb3fba2484c5b541cb82c4e162/0129451354v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/d8/31/d831a92b2862f06b828503add415bd9a/0129449661v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/be/e1/bee13b8d51a419b9b8f0685e2b9d47bf/0128917673v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/51/7a/517a4e83c5827663b4839f5ddb98f434/0128872953v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/d5/72/d5728578b35b72f365f5086bc1d068da/0128662441v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/a9/69/a96920e47e362a9cf0b9916b7ad3d30a/0128071795v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/18/47/1847e6b1456c96f04bd511bbd21f3779/0129039479v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/3b/fd/3bfda4bbcb1a60004c330bde3b705109/0128453300v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/cc/19/cc19aa5fec6f6f2b25dbd9516efed735/0128077403v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/de/66/de66dd32e1af2fa37ff20bded4417afc/0127787418v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/6b/cc/6bcc3d26e1c7c74d90a10bc3ca296ae1/0128362351v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/24/c8/24c84ab6b1bcd24468a87820a07a85aa/0128194707v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/1d/3e/1d3e2788eb37c1e974f36337c8d33cb5/0128191010v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/19/76/1976928d7d0a2ed7c1eeba7ade8552c8/0126365603v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/0c/04/0c045977492b7af382831470a813c15f/0129625714v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/99/d2/99d2e5e83062b4cf2aa3dc0a60d15f23/0129624804v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/20/22/202266f978d422d655fa5909dfb54fd5/0129592446v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/98/f0/98f06d033c1aafbfe6b9b0e22abd0303/0129590496v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/f8/29/f8298429c1638b949a6f76346f6709c7/0118701710v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/07/24/07242664ab2b1c7841c9d9d0a127670c/0116045959.jpeg)

:quality(80)/p7i.vogel.de/wcms/c9/79/c979a20b32395ddfa93fe7ead90578a0/0108386061.jpeg)

:quality(80)/p7i.vogel.de/wcms/9e/5c/9e5c92d942ed046a27562d6e3d730c92/0103483548.jpeg)

:quality(80)/p7i.vogel.de/wcms/16/3d/163da381529db3a47348a9440655529b/0125732969v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/e7/82/e782bbbf96e4971c22241d76e5de1720/0124855387v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/f9/40/f940b2630f4805f08212fd851af46d6d/0124788233v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/3a/6d/3a6d046cf1db266c3009cecb2af8e2b7/0124656182v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/a8/4e/a84e8039a90a5cf4751d01ebcf6ba1a9/0127510172v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/17/c7/17c703445f134eb3d7ecc7918dda2762/0124596096v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/2a/2c/2a2cffc07f51019065387cd63241b5ce/0119463370v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/b1/7e/b17ea8c62ccafad1d1fb072d6199bbd6/0118578446.jpeg)

:quality(80)/p7i.vogel.de/wcms/d1/a8/d1a83b822e16733380268322d033abdc/0129239584v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/bb/54/bb54162539c6fc9ac135719af078ea06/0129188218v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/02/02/020250273eb250f46d355a16c1baeb74/0129163933v2.jpeg)

:fill(fff,0)/images.vogel.de/vogelonline/companyimg/107800/107832/65.jpg)

:fill(fff,0)/images.vogel.de/vogelonline/companyimg/2000/2093/65.jpg)

:fill(fff,0)/images.vogel.de/vogelonline/companyimg/101800/101879/65.jpg)

:quality(80)/p7i.vogel.de/wcms/b4/6f/b46f24c562a10a8c0c40b1f9c509ed45/0124276026v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/19/76/1976928d7d0a2ed7c1eeba7ade8552c8/0126365603v1.jpeg)