Related Vendors

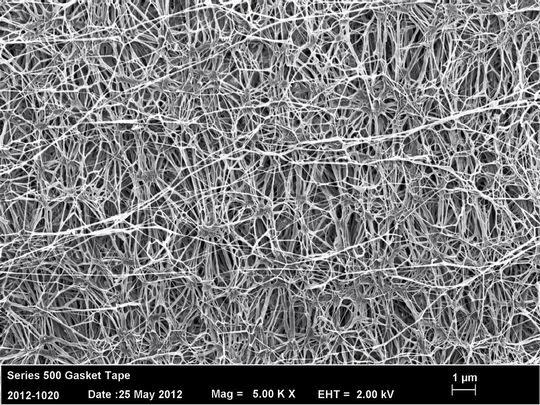

By introducing the Gore Joint Sealant, Gore launched the first gasket tape made of expanded PTFE (ePTFE) back in 1971. However, multiaxially expanded PTFE technology finally made it easier to use ePTFE with shell and tube heat exchangers across a broader range of application conditions.

The need for these material performance improvements by Gore is the low creep resistance of PTFE. In molecular terms, PTFE consists of a chain of carbon atoms that is saturated with fluorine atoms. The strong covalent carbon-fluorine bond is responsible for this polymer’s nearly inert chemical reaction behavior.

This explains why this material is desired as a sealing material in aggressive media. However, the lack of reactivity also means that PTFE chains cannot be molecularly linked like other materials, elastomers for example, and this results in a profound cold and warm flow behavior, also known as “creeping”.

Risk of Deformation of the Sealing Material

Creeping refers to the mechanical deformation of a component – in this case the seal – when subjected to loads and temperatures. One reason why seals in flange connections function is because the surface pressure caused by the bolts allows for irregularities in the sealing surfaces to be filled up and for blocking of leakage channels inside the seal.

:quality(80)/images.vogel.de/vogelonline/bdb/420800/420847/original.jpg)

Heat Exchangers

Energy Awareness Drives Heat Exchanger Market

This reduces leakage (depending on the behavior of the sealing material) to an acceptable level. In this sense, leakage refers to the admissible substance flow, irrespective of the prevailing mechanism, in other words the sum of all mass flows from Fick’s law of diffusion to gross leakage.

This sealing function is severely impaired by the creep tendency. Inside a flange connection, creep of a sealing material takes place in such a way that the load is reduced at a certain temperature until a balance between the internal strength of the seal and the external load is achieved. This behavior is called creep resistance.

(ID:43333945)

:quality(80)/p7i.vogel.de/wcms/40/8f/408f074f8094bca2cd9bb078e79eccb0/0129580192v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/f3/4a/f34abcf99d71d8bff5a4e98b60889c8e/0129239597v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/5c/27/5c27bddaef122b61c636e31d82a33bd9/0129017834v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/f7/f0/f7f0fdf4a4e1d872d078d63abfa4a7fd/0127844838v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/0a/1c/0a1c5f661e1df4b35d4cd8e4901e4035/0129624833v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/9f/7f/9f7f9d5256b75ba8141a63bbf981b793/0129506442v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/ed/af/edaf3b0b2506f65f338232550b661eb3/0129281129v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/66/29/66293f3c9de08b472f095dc9602bcc7d/0129279548v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/d7/9e/d79e4ba6b9e0923d1513b843962712d9/0129591121v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/26/12/261210e5920899e5c35c4f905d3be8bd/0129399814v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/3e/e6/3ee6ff7ac2852491ce36fd6cb84bb7f0/0129534719v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/fc/42/fc420e2134a13a67212be7e5f68c63d6/0129419035v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/3c/09/3c090686df20769698f3203d11960151/0129534706v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/69/3c/693cd37dc03f7a3be3f6e40cdac3ccca/0129534194v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/69/08/6908c3bb3fba2484c5b541cb82c4e162/0129451354v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/d8/31/d831a92b2862f06b828503add415bd9a/0129449661v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/be/e1/bee13b8d51a419b9b8f0685e2b9d47bf/0128917673v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/51/7a/517a4e83c5827663b4839f5ddb98f434/0128872953v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/d5/72/d5728578b35b72f365f5086bc1d068da/0128662441v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/a9/69/a96920e47e362a9cf0b9916b7ad3d30a/0128071795v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/18/47/1847e6b1456c96f04bd511bbd21f3779/0129039479v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/3b/fd/3bfda4bbcb1a60004c330bde3b705109/0128453300v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/cc/19/cc19aa5fec6f6f2b25dbd9516efed735/0128077403v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/de/66/de66dd32e1af2fa37ff20bded4417afc/0127787418v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/6b/cc/6bcc3d26e1c7c74d90a10bc3ca296ae1/0128362351v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/24/c8/24c84ab6b1bcd24468a87820a07a85aa/0128194707v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/1d/3e/1d3e2788eb37c1e974f36337c8d33cb5/0128191010v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/19/76/1976928d7d0a2ed7c1eeba7ade8552c8/0126365603v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/0c/04/0c045977492b7af382831470a813c15f/0129625714v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/99/d2/99d2e5e83062b4cf2aa3dc0a60d15f23/0129624804v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/20/22/202266f978d422d655fa5909dfb54fd5/0129592446v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/98/f0/98f06d033c1aafbfe6b9b0e22abd0303/0129590496v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/f8/29/f8298429c1638b949a6f76346f6709c7/0118701710v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/07/24/07242664ab2b1c7841c9d9d0a127670c/0116045959.jpeg)

:quality(80)/p7i.vogel.de/wcms/c9/79/c979a20b32395ddfa93fe7ead90578a0/0108386061.jpeg)

:quality(80)/p7i.vogel.de/wcms/9e/5c/9e5c92d942ed046a27562d6e3d730c92/0103483548.jpeg)

:quality(80)/p7i.vogel.de/wcms/16/3d/163da381529db3a47348a9440655529b/0125732969v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/e7/82/e782bbbf96e4971c22241d76e5de1720/0124855387v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/f9/40/f940b2630f4805f08212fd851af46d6d/0124788233v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/3a/6d/3a6d046cf1db266c3009cecb2af8e2b7/0124656182v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/a8/4e/a84e8039a90a5cf4751d01ebcf6ba1a9/0127510172v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/17/c7/17c703445f134eb3d7ecc7918dda2762/0124596096v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/2a/2c/2a2cffc07f51019065387cd63241b5ce/0119463370v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/b1/7e/b17ea8c62ccafad1d1fb072d6199bbd6/0118578446.jpeg)

:quality(80)/p7i.vogel.de/wcms/d1/a8/d1a83b822e16733380268322d033abdc/0129239584v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/bb/54/bb54162539c6fc9ac135719af078ea06/0129188218v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/02/02/020250273eb250f46d355a16c1baeb74/0129163933v2.jpeg)

:fill(fff,0)/images.vogel.de/vogelonline/companyimg/107800/107832/65.jpg)

:fill(fff,0)/images.vogel.de/vogelonline/companyimg/2000/2093/65.jpg)

:fill(fff,0)/images.vogel.de/vogelonline/companyimg/101800/101879/65.jpg)

:quality(80)/p7i.vogel.de/wcms/b4/6f/b46f24c562a10a8c0c40b1f9c509ed45/0124276026v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/19/76/1976928d7d0a2ed7c1eeba7ade8552c8/0126365603v1.jpeg)