Related Vendors

Hydrodynamic Cavitation Technology

Hydrodynamic cavitation technology uses a rotor with precisely machined cavities spinning in a liquid chamber that generates controlled cavitation. The process generates and collapses bubbles due to the decrease and then increase in the pressure produced.

As the bubbles collapse, a powerful energy wave (shockwave) is released into the surrounding liquid. This cavitation shockwave creates an efficient microscopic mixing effect which along with the rotor or liquid friction generates controllable, scale-free heating.

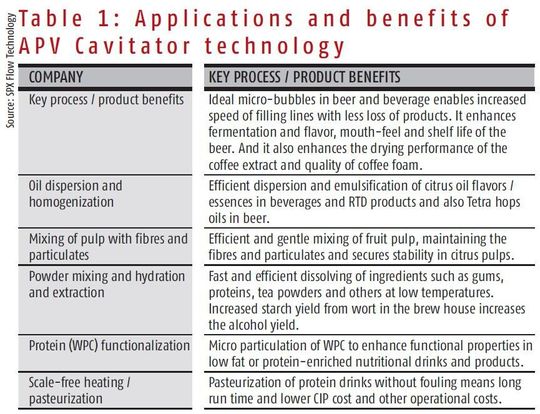

The APV Cavitator has multiple applications including gas dispersion; citrus oil dispersion and homogenization, gentle mixing of fruit pulps, powder ingredients hydration and functionalization and scale free heating of protein drinks. The applications are represented in Table 1 and some of these applications will be further discussed here.

Unique Gas Dispersion Enhances Filling Efficiency

Gas dispersion is a unique and proven feature of the Cavitator. Thanks to its efficient gas dispersion, the ideal condition for micro-bubbles are generated in the carbonation (CO2) or the nitrogenation (N2) processes in the final beer. O2 is essential for yeast and a good dispersion of the O2 promotes the fermentation process. The CO2 and N2 enhance flavor, mouth-feel and shelf life in soft drinks, beer and cider, etc., when well dispersed as micro bubbles.

The APV Cavitator has proven high efficiency in the carbonation of beer prior to filling. The Cavitator produces fine micro bubbles when the solution is supersaturated; this significantly improves the bottle line efficiency.

(ID:43510172)

:quality(80)/p7i.vogel.de/wcms/60/25/60259e0165560492b717049a5006b5d2/0129719891v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/40/8f/408f074f8094bca2cd9bb078e79eccb0/0129580192v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/f3/4a/f34abcf99d71d8bff5a4e98b60889c8e/0129239597v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/5c/27/5c27bddaef122b61c636e31d82a33bd9/0129017834v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/3f/e3/3fe39c03ebb8bb0d4b4f46099ebd99e4/0129746348v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/cc/2a/cc2adab5b0d9dfe126364d289a5f16f1/0129688606v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/0a/1c/0a1c5f661e1df4b35d4cd8e4901e4035/0129624833v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/9f/7f/9f7f9d5256b75ba8141a63bbf981b793/0129506442v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/26/12/261210e5920899e5c35c4f905d3be8bd/0129399814v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/d7/9e/d79e4ba6b9e0923d1513b843962712d9/0129591121v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/3e/e6/3ee6ff7ac2852491ce36fd6cb84bb7f0/0129534719v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/fc/42/fc420e2134a13a67212be7e5f68c63d6/0129419035v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/91/d3/91d363e4abe71708f00b7205b2d32eff/0129746143v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/30/65/3065b16f11e1f1bbbb6fad217b735696/0129728979v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/27/76/277629e55f32cc82a35719ecb903496a/0129687208v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/01/9b/019b59f3ef2e852ec5058ba18f323af2/0129651573v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/be/e1/bee13b8d51a419b9b8f0685e2b9d47bf/0128917673v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/51/7a/517a4e83c5827663b4839f5ddb98f434/0128872953v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/d5/72/d5728578b35b72f365f5086bc1d068da/0128662441v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/a9/69/a96920e47e362a9cf0b9916b7ad3d30a/0128071795v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/c4/54/c454c7d8fd344c0ffc2ef5db00ad632f/0129728429v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/18/47/1847e6b1456c96f04bd511bbd21f3779/0129039479v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/3b/fd/3bfda4bbcb1a60004c330bde3b705109/0128453300v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/cc/19/cc19aa5fec6f6f2b25dbd9516efed735/0128077403v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/6b/cc/6bcc3d26e1c7c74d90a10bc3ca296ae1/0128362351v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/24/c8/24c84ab6b1bcd24468a87820a07a85aa/0128194707v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/1d/3e/1d3e2788eb37c1e974f36337c8d33cb5/0128191010v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/19/76/1976928d7d0a2ed7c1eeba7ade8552c8/0126365603v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/e7/cc/e7cc48a384ef2e790f79f1de7f54597b/0129729765v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/4a/80/4a8098395b0ced59ef40683f84ab30eb/0129685918v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/fc/c4/fcc4af0d5d9a0ebe17305f4983a2c2f1/0129668183v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/e4/a1/e4a1f8a6d645cb9b0c758f2bc89f3e22/0129667956v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/f8/29/f8298429c1638b949a6f76346f6709c7/0118701710v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/07/24/07242664ab2b1c7841c9d9d0a127670c/0116045959.jpeg)

:quality(80)/p7i.vogel.de/wcms/c9/79/c979a20b32395ddfa93fe7ead90578a0/0108386061.jpeg)

:quality(80)/p7i.vogel.de/wcms/9e/5c/9e5c92d942ed046a27562d6e3d730c92/0103483548.jpeg)

:quality(80)/p7i.vogel.de/wcms/16/3d/163da381529db3a47348a9440655529b/0125732969v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/e7/82/e782bbbf96e4971c22241d76e5de1720/0124855387v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/f9/40/f940b2630f4805f08212fd851af46d6d/0124788233v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/3a/6d/3a6d046cf1db266c3009cecb2af8e2b7/0124656182v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/a8/4e/a84e8039a90a5cf4751d01ebcf6ba1a9/0127510172v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/17/c7/17c703445f134eb3d7ecc7918dda2762/0124596096v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/2a/2c/2a2cffc07f51019065387cd63241b5ce/0119463370v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/b1/7e/b17ea8c62ccafad1d1fb072d6199bbd6/0118578446.jpeg)

:quality(80)/p7i.vogel.de/wcms/99/d2/99d2e5e83062b4cf2aa3dc0a60d15f23/0129624804v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/d1/a8/d1a83b822e16733380268322d033abdc/0129239584v2.jpeg)

:fill(fff,0)/images.vogel.de/vogelonline/companyimg/113800/113818/65.jpg)

:fill(fff,0)/images.vogel.de/vogelonline/companyimg/101800/101879/65.jpg)

:fill(fff,0)/p7i.vogel.de/companies/68/c8/68c815bc8fe81/prominent-logo-300x300.jpeg)

:quality(80)/p7i.vogel.de/wcms/4d/01/4d0190b74132a4ba922e18e5593493f3/0126235883v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/26/12/261210e5920899e5c35c4f905d3be8bd/0129399814v2.jpeg)