Related Vendors

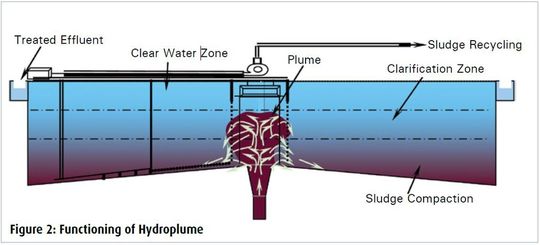

The wastewater containing mixed liquor suspended solids (MLSS) enters through a low level gradually enlarged inlet to dissipate substantial hydraulic energy of the incoming wastewater. Gradual increase in pipe diameter reduces velocity of the incoming wastewater, which results in decrease in hydraulic energy and also prevents jetting. This further leads to uniform distribution of wastewater at the bottom. When the liquid level starts rising in the clarifier, the solids present in wastewater collide with each other just above the gradually enlarged outlet, thereby undergoing natural flocculation and forming bigger flocs.

These flocs further form plume, which rises vertically upwards to some distance. The plume comprising flocs, being heavier than the liquid (water) and after having lost substantial hydraulic energy, settle at the bottom of the clarifier. The plume settles quickly as one unit at the sloped bottom forms a sludge blanket. Constant incoming flow of wastewater, containing MLSS, keeps forming sludge clouds and each layer settles over the other and forms sludge blanket continuously.

Dispensing the Hydraulic Energy

Initially, the gradually enlarged inlet dissipates the hydraulic energy of the incoming wastewater and then the bulk mass of dense solids present in the plume offers resistance to incoming flow, thereby further reducing the hydraulic energy. The formation of plume and hydraulic energy dissipation go hand-in-hand. The plume helps in dampening the velocity of solids present in the wastewater and the solids help in forming the plume. Formation of a well-defined plume indicates that absolute quiescent conditions prevail in the clarifier and therefore, it is an indication of efficient solid-liquid separation. This way, solids are separated from liquid and settle in the form of sludge blanket at the bottom of the clarifier (Figure 2).

:quality(80)/images.vogel.de/vogelonline/bdb/376100/376159/original.jpg)

Water Treatment

Water Treatment in Industrialised India

The settled sludge is removed uniformly using a suction mechanism comprising a suction pump and suction tube manifolds, which is rested on a platform and discharged to either the aeration tank or for sludge thickening through a stationary sludge outlet. A baffle wall is provided as a precautionary measure to prevent escape of solids, in case some air bubbles come along with the wastewater and disturb the plume.

The treated effluent separated from solids rises in the clarifier and collects uniformly in the launder through effluent weirs, thereby providing clarified treated effluent.

Separating Colloidal Particles: A Technical Innovation

The main advantage of the clarifier that works on the principle of developing a Source: CSIR-NEERI plume is that the spatial grid of flocs filters out even colloidal particles due to absorption and adhesion. Formation of plume largely depends upon the velocity gradient that provides natural flocculation in the Hydroplume. The plume rise or plume height depends upon the velocity gradient.

(ID:42582617)

:quality(80)/p7i.vogel.de/wcms/5c/27/5c27bddaef122b61c636e31d82a33bd9/0129017834v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/f7/f0/f7f0fdf4a4e1d872d078d63abfa4a7fd/0127844838v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/1e/50/1e5099910c2370ad08d578161f3fe3c2/0128939735v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/56/ec/56ecda05b645f0174c02631d95ca9aa4/0128668888v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/e7/40/e74003abab999d9c5ff06672ed899136/0128971984v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/0b/c2/0bc2d35b3728c6155bcdc18aa0b4f43e/0128940631v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/ad/82/ad8217d5688276d9ed82b41be17e2edb/0128939746v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/fa/04/fa0408f795513d992edc5f098924e404/0128934009v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/2c/87/2c879e9ba1bd966c7003802f0b8e1149/0128880738v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/f2/d4/f2d42a2b7ad97329aeafb49c514f63f3/0128879848v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/94/f2/94f2a278fd90b0da7400966874f44950/0128605000v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/1f/52/1f528d0628ffe679a69a2e9f65c0e157/0128668896v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/cf/5b/cf5b66e0b2268fdadb5e20fd585edebb/0128971089v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/c1/67/c167f473ddeca77220259be63c52e80f/0128933152v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/51/7a/517a4e83c5827663b4839f5ddb98f434/0128872953v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/be/e1/bee13b8d51a419b9b8f0685e2b9d47bf/0128917673v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/d5/72/d5728578b35b72f365f5086bc1d068da/0128662441v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/a9/69/a96920e47e362a9cf0b9916b7ad3d30a/0128071795v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/3b/fd/3bfda4bbcb1a60004c330bde3b705109/0128453300v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/cc/19/cc19aa5fec6f6f2b25dbd9516efed735/0128077403v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/de/66/de66dd32e1af2fa37ff20bded4417afc/0127787418v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/d5/78/d578d9a15e78a46fad46847d963a04c2/0127547393v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/6b/cc/6bcc3d26e1c7c74d90a10bc3ca296ae1/0128362351v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/24/c8/24c84ab6b1bcd24468a87820a07a85aa/0128194707v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/1d/3e/1d3e2788eb37c1e974f36337c8d33cb5/0128191010v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/19/76/1976928d7d0a2ed7c1eeba7ade8552c8/0126365603v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/d8/26/d826876f8d4e1cb9be238005f31da84a/0129019696v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/9b/19/9b191cc35990bcfae941dcc78e49016e/0129018835v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/d4/ba/d4ba61e95ad0cdd0e150bb37d0f93afe/0128971702v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/b1/3e/b13e690924b3d0318ad71289acfd6b82/0128934399v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/f8/29/f8298429c1638b949a6f76346f6709c7/0118701710v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/07/24/07242664ab2b1c7841c9d9d0a127670c/0116045959.jpeg)

:quality(80)/p7i.vogel.de/wcms/c9/79/c979a20b32395ddfa93fe7ead90578a0/0108386061.jpeg)

:quality(80)/p7i.vogel.de/wcms/9e/5c/9e5c92d942ed046a27562d6e3d730c92/0103483548.jpeg)

:quality(80)/p7i.vogel.de/wcms/16/3d/163da381529db3a47348a9440655529b/0125732969v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/e7/82/e782bbbf96e4971c22241d76e5de1720/0124855387v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/f9/40/f940b2630f4805f08212fd851af46d6d/0124788233v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/3a/6d/3a6d046cf1db266c3009cecb2af8e2b7/0124656182v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/a8/4e/a84e8039a90a5cf4751d01ebcf6ba1a9/0127510172v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/17/c7/17c703445f134eb3d7ecc7918dda2762/0124596096v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/2a/2c/2a2cffc07f51019065387cd63241b5ce/0119463370v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/b1/7e/b17ea8c62ccafad1d1fb072d6199bbd6/0118578446.jpeg)

:quality(80)/p7i.vogel.de/wcms/a3/f6/a3f6cf659bef4a255272c8af711c20af/0128599957v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/d7/b4/d7b4415fef8a0be11c7f8fd4197edc92/0128599865v2.jpeg)

:fill(fff,0)/images.vogel.de/vogelonline/companyimg/2000/2093/65.jpg)

:fill(fff,0)/images.vogel.de/vogelonline/companyimg/103000/103097/65.jpg)

:fill(fff,0)/p7i.vogel.de/companies/68/c8/68c815bc8fe81/prominent-logo-300x300.jpeg)

:quality(80)/p7i.vogel.de/wcms/a9/e7/a9e72afad4d68bc6e348bdbf394c6f1a/0123403452v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/c1/ed/c1ed89188a8fdb351601e36204d4c38b/0125059797v2.jpeg)