Related Vendors

Pressure Drops Within the Column

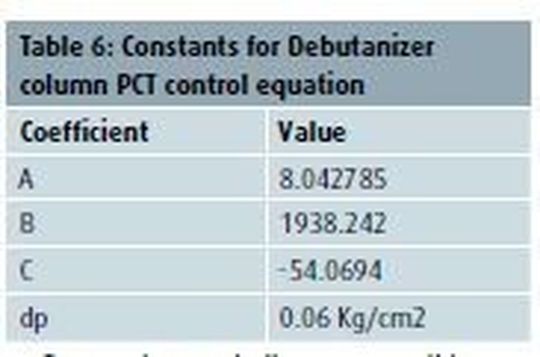

Antoine’s equation (eq. 3) can be updated for debutanizer PCT as below –

Where, dp = Pressure drop from pressure measurement to temperature point (kg/cm2) (assumed constant) (It is subtracted from Pmeasured as pressure measurement point is below the temperature point in the column).

When the control temperature and control pressure are measured at two different locations in the column, pressure drop between the measuring points needs to be added or subtracted depending on the location of respective transmitters. E.g. if the pressure transmitter is located below the temperature transmitter, pressure drop across respective transmitters shall be subtracted to get the column pressure at the tray where temperature transmitter is located. In case of Deisobutanizer column, pressure transmitter and temperature transmitter were located at the same tray, thus dp term was set to zero.

Fine Tuning Required for Pressure Control

Results: Antoine’s equation (eq. 4) is used to get corrected temperature after pressure compensation.

Temperature controller compares this corrected temperature with actual measured temperature and takes corrective action. The values of the coefficients of the equation are determined from regression data analysis tool of MS Excel 2010 and are mentioned in table 6. Pressure drop term “dp” is worked out from actual vendor data. Since values of these coefficients are derived from the simulated data and not from actual plant operating data, these coefficients need to be fine-tuned during actual operation of column.

(ID:38049620)

:quality(80)/p7i.vogel.de/wcms/f3/4a/f34abcf99d71d8bff5a4e98b60889c8e/0129239597v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/5c/27/5c27bddaef122b61c636e31d82a33bd9/0129017834v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/f7/f0/f7f0fdf4a4e1d872d078d63abfa4a7fd/0127844838v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/1e/50/1e5099910c2370ad08d578161f3fe3c2/0128939735v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/ed/af/edaf3b0b2506f65f338232550b661eb3/0129281129v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/66/29/66293f3c9de08b472f095dc9602bcc7d/0129279548v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/5b/e1/5be15b3ec731f81589ae9b16a43ac54c/0129243604v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/40/6d/406de78846e840f6c7cf7849cbf0ab08/0129163370v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/2c/87/2c879e9ba1bd966c7003802f0b8e1149/0128880738v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/f2/d4/f2d42a2b7ad97329aeafb49c514f63f3/0128879848v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/94/f2/94f2a278fd90b0da7400966874f44950/0128605000v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/1f/52/1f528d0628ffe679a69a2e9f65c0e157/0128668896v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/6f/c4/6fc4c90b3bf74992ead5f24e7593ccf1/0129320690v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/d0/1b/d01bf797fa89982391d0ac726c3d69aa/0129278531v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/03/11/031137c1a0c2b4407960a762fd0fd915/0129189201v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/47/4f/474fac12fca989a8d8db63de335dd78d/0129188583v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/be/e1/bee13b8d51a419b9b8f0685e2b9d47bf/0128917673v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/51/7a/517a4e83c5827663b4839f5ddb98f434/0128872953v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/d5/72/d5728578b35b72f365f5086bc1d068da/0128662441v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/a9/69/a96920e47e362a9cf0b9916b7ad3d30a/0128071795v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/18/47/1847e6b1456c96f04bd511bbd21f3779/0129039479v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/3b/fd/3bfda4bbcb1a60004c330bde3b705109/0128453300v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/cc/19/cc19aa5fec6f6f2b25dbd9516efed735/0128077403v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/de/66/de66dd32e1af2fa37ff20bded4417afc/0127787418v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/6b/cc/6bcc3d26e1c7c74d90a10bc3ca296ae1/0128362351v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/24/c8/24c84ab6b1bcd24468a87820a07a85aa/0128194707v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/1d/3e/1d3e2788eb37c1e974f36337c8d33cb5/0128191010v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/19/76/1976928d7d0a2ed7c1eeba7ade8552c8/0126365603v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/53/5e/535e7f33b12b692072f51c4088f290fb/0129340389v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/96/82/9682dc33638af037ca77cc462bd24db8/0129340377v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/21/09/2109113b58ce31bc2fdf291363c0dab1/0129319863v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/25/f0/25f082c070a1153bdac9ceadc80dc68f/0129319370v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/f8/29/f8298429c1638b949a6f76346f6709c7/0118701710v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/07/24/07242664ab2b1c7841c9d9d0a127670c/0116045959.jpeg)

:quality(80)/p7i.vogel.de/wcms/c9/79/c979a20b32395ddfa93fe7ead90578a0/0108386061.jpeg)

:quality(80)/p7i.vogel.de/wcms/9e/5c/9e5c92d942ed046a27562d6e3d730c92/0103483548.jpeg)

:quality(80)/p7i.vogel.de/wcms/16/3d/163da381529db3a47348a9440655529b/0125732969v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/e7/82/e782bbbf96e4971c22241d76e5de1720/0124855387v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/f9/40/f940b2630f4805f08212fd851af46d6d/0124788233v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/3a/6d/3a6d046cf1db266c3009cecb2af8e2b7/0124656182v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/a8/4e/a84e8039a90a5cf4751d01ebcf6ba1a9/0127510172v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/17/c7/17c703445f134eb3d7ecc7918dda2762/0124596096v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/2a/2c/2a2cffc07f51019065387cd63241b5ce/0119463370v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/b1/7e/b17ea8c62ccafad1d1fb072d6199bbd6/0118578446.jpeg)

:quality(80)/p7i.vogel.de/wcms/d1/a8/d1a83b822e16733380268322d033abdc/0129239584v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/bb/54/bb54162539c6fc9ac135719af078ea06/0129188218v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/02/02/020250273eb250f46d355a16c1baeb74/0129163933v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/3f/69/3f69ed74aeaa46ac08dcd9fbe1f2d497/0129141343v2.jpeg)

:fill(fff,0)/images.vogel.de/vogelonline/companyimg/107800/107832/65.jpg)

:fill(fff,0)/p7i.vogel.de/companies/68/07/6807ad98568ce/logo-elementar-rgb.jpeg)

:fill(fff,0)/images.vogel.de/vogelonline/companyimg/2000/2093/65.jpg)

:quality(80)/p7i.vogel.de/wcms/f4/6a/f46a302c01502dc8c0a4003999112f0f/0128662450v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/aa/9f/aa9f87b6bd7ccdd61e3a0777ef37f701/0128191833v2.jpeg)