Related Vendors

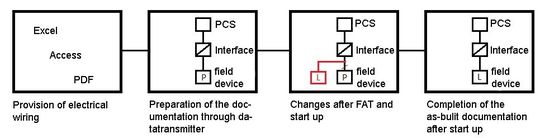

The documentation specialists subsequently worked on all planning documents such as cable lists, terminal lists, field device information and DCS information in an agreed format. These PDF, excel and access files were then imported via the internal ProDOK data transmitter into almost finished ProDOK circuit diagrams. After minimal adjustments a rough draft of the documentation emerged, which was then available on-site.

“Now we experienced the value of LiveDOK”, says Wildgrube, “The plant, now rough drafted, finished planned and documented was now subjected to extensive late changes, which inevitably always happens in large projects. In addition, signal pathways which could not be simply imported had to be outlined, as they were too complex for the standard import routines and too small in number that it would not have been worth adjusting these routines.

Benefits of Electronic Plant Documentation

For this LiveDOK, the electronic documentation system, which was specifically developed to support the plants maintenance and support operations, offers ideal functionality. Open to all tasks, quick and intuitive use LiveDOK accompanies the complete documentation life cycle, beginning with the preparation via comfortable use up to the revision of altered documents.

The ‘heart’ of the documentation software, the high-performance LiveDOK generator, prepared for all conceivable tasks, takes care of this. It processes all common formats and can, therefore, manage floor layouts (cabinet planning, etc.), site plans, process flow diagrams, I&C site lists, safety related documentation, operating instructions, testing requirements, maintenance instructions, as well as process oriented documentations to name a few. There are also several possibilities to document changes. For example, the redlining palette ranges from handwritten input to highlighting, crossing out and much more, up to a dynamic stamping of changes. In this way, even specific challenging tasks can be resolved effectively and comfortably by using seamlessly integrated tools.

Late Changes Made Easy

“During the planning phase it was not exactly known which requirements would be implemented for the shutdown”, says Wildgrube. “However we were able to implement the basic functionality and document it as a rough draft. The specified procedure during the FAT (Factory Acceptance Test) to ‘connect’ the field level to the control level was documented with LiveDOK and continuously maintained by LiveDOK, so that it was possible to deliver the real ‘as-built’ documentation right after the successful start-up.”

The fact that details from all field devices were not immediately evident or communicated accordingly turned out to be unproblematic. The missing information was collected later as part of the signal testing and updated in LiveDOK, ensuring full and correct documentation in combination with the original data for the time being.

(ID:43225860)

:quality(80)/p7i.vogel.de/wcms/f3/4a/f34abcf99d71d8bff5a4e98b60889c8e/0129239597v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/5c/27/5c27bddaef122b61c636e31d82a33bd9/0129017834v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/f7/f0/f7f0fdf4a4e1d872d078d63abfa4a7fd/0127844838v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/1e/50/1e5099910c2370ad08d578161f3fe3c2/0128939735v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/ed/af/edaf3b0b2506f65f338232550b661eb3/0129281129v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/66/29/66293f3c9de08b472f095dc9602bcc7d/0129279548v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/5b/e1/5be15b3ec731f81589ae9b16a43ac54c/0129243604v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/40/6d/406de78846e840f6c7cf7849cbf0ab08/0129163370v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/2c/87/2c879e9ba1bd966c7003802f0b8e1149/0128880738v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/f2/d4/f2d42a2b7ad97329aeafb49c514f63f3/0128879848v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/94/f2/94f2a278fd90b0da7400966874f44950/0128605000v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/1f/52/1f528d0628ffe679a69a2e9f65c0e157/0128668896v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/69/08/6908c3bb3fba2484c5b541cb82c4e162/0129451354v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/d8/31/d831a92b2862f06b828503add415bd9a/0129449661v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/8d/a1/8da1c8bc8ce0fc8270a280ab1908bfc7/0129389288v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/6f/c4/6fc4c90b3bf74992ead5f24e7593ccf1/0129320690v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/be/e1/bee13b8d51a419b9b8f0685e2b9d47bf/0128917673v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/51/7a/517a4e83c5827663b4839f5ddb98f434/0128872953v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/d5/72/d5728578b35b72f365f5086bc1d068da/0128662441v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/a9/69/a96920e47e362a9cf0b9916b7ad3d30a/0128071795v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/18/47/1847e6b1456c96f04bd511bbd21f3779/0129039479v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/3b/fd/3bfda4bbcb1a60004c330bde3b705109/0128453300v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/cc/19/cc19aa5fec6f6f2b25dbd9516efed735/0128077403v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/de/66/de66dd32e1af2fa37ff20bded4417afc/0127787418v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/6b/cc/6bcc3d26e1c7c74d90a10bc3ca296ae1/0128362351v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/24/c8/24c84ab6b1bcd24468a87820a07a85aa/0128194707v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/1d/3e/1d3e2788eb37c1e974f36337c8d33cb5/0128191010v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/19/76/1976928d7d0a2ed7c1eeba7ade8552c8/0126365603v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/53/82/5382b72160f544c88671963328df1876/0129471274v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/9c/4c/9c4c1285656a01971aa4f3779002fde5/0129470303v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/ec/e4/ece471df12b2a2c5beae69c92a21730f/0129469695v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/ce/57/ce57e2593263485e488b2414f289f06c/0129390574v4.jpeg)

:quality(80)/p7i.vogel.de/wcms/f8/29/f8298429c1638b949a6f76346f6709c7/0118701710v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/07/24/07242664ab2b1c7841c9d9d0a127670c/0116045959.jpeg)

:quality(80)/p7i.vogel.de/wcms/c9/79/c979a20b32395ddfa93fe7ead90578a0/0108386061.jpeg)

:quality(80)/p7i.vogel.de/wcms/9e/5c/9e5c92d942ed046a27562d6e3d730c92/0103483548.jpeg)

:quality(80)/p7i.vogel.de/wcms/16/3d/163da381529db3a47348a9440655529b/0125732969v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/e7/82/e782bbbf96e4971c22241d76e5de1720/0124855387v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/f9/40/f940b2630f4805f08212fd851af46d6d/0124788233v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/3a/6d/3a6d046cf1db266c3009cecb2af8e2b7/0124656182v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/a8/4e/a84e8039a90a5cf4751d01ebcf6ba1a9/0127510172v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/17/c7/17c703445f134eb3d7ecc7918dda2762/0124596096v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/2a/2c/2a2cffc07f51019065387cd63241b5ce/0119463370v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/b1/7e/b17ea8c62ccafad1d1fb072d6199bbd6/0118578446.jpeg)

:quality(80)/p7i.vogel.de/wcms/d1/a8/d1a83b822e16733380268322d033abdc/0129239584v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/bb/54/bb54162539c6fc9ac135719af078ea06/0129188218v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/02/02/020250273eb250f46d355a16c1baeb74/0129163933v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/3f/69/3f69ed74aeaa46ac08dcd9fbe1f2d497/0129141343v2.jpeg)

:fill(fff,0)/images.vogel.de/vogelonline/companyimg/107800/107832/65.jpg)

:fill(fff,0)/images.vogel.de/vogelonline/companyimg/2000/2093/65.jpg)

:fill(fff,0)/p7i.vogel.de/companies/61/f9/61f9439b7cbe4/logo-edl.png)

:quality(80)/p7i.vogel.de/wcms/01/15/0115415d906c21a45a3843617426db74/0125679758v3.jpeg)

:quality(80)/p7i.vogel.de/wcms/3a/d6/3ad65ecb7337a63b629428c256461943/0127773467v2.jpeg)