Related Vendors

In addition, La Cygne suffered high NH3 slip (unused reagent that ‘slips’ through the catalyst unreacted) as the catalyst activity decreased. This increase in slip caused operational issues downstream of the reactor including pressure loss increases over the air pre–heater and more frequent APH washings.

In 2012, the ash accumulation rate increased to twice the typical amount as the power plant operated for an extended time with a low demand factor. Although many minor changes were made to the system to improve the performance over the course of the previous years, none of them were successful as they did not address the root cause of the problems.

Reactor Design, Optimised with CFD

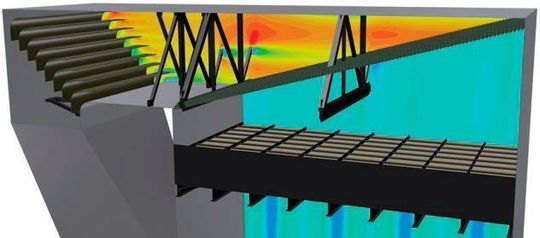

However, the GSG technology developed and designed by Fuel Tech successfully addressed all of these complexities, and produced a significant improvement compared to traditional turning vane techniques. Fuel Tech was contracted by KCP&L in 2012 to perform a thorough CFD optimization and EFD validation study, and, later, to provide equipment and equipment performance guarantees based on the results of this study. The resulting gas flow profile in the inlet hood of the reactor is shown in Figure 4.

The unit was restarted in 2013 with a notable reduction in catalyst pluggage due to ash precipitation and the retrofit has been deemed a large success. According to the paper by KCP&L engineer, Scott Heideman (Heideman, 2013) the GSG has resulted in annual operational savings of $5 million.

It is notable that the next catalyst layer replacement for this unit is not budgeted until 2019. This means that only one layer needs to be replaced over the next seven years, which is a major improvement compared to eight layer replacements over the course of the last five years.

Fuel Tech and the Birth of I–NOx Integrated

NOx reduction, or I-NOx, is an advanced NOx removal technology that successfully addresses all the challenging aspects of an SCR unit and takes it to a higher level of performance while maintaining a low capital cost.

:quality(80)/images.vogel.de/vogelonline/bdb/534900/534909/original.jpg)

Coal and Ash Handling

High Concentration Slurry Disposal Accepted at Power Plants

This technology was first introduced by Fuel Tech to be a combination of their CFD-guided staged approach for NOx reduction including advanced combustion modifications consisting of Low-NOx-Burners (LNB) and Over Fire Air (OFA), and post combustion de-NOx approaches including Selective Non-Catalytic Reduction (SNCR), and Selective Catalytic Reduction (SCR).

(ID:43684515)

:quality(80)/p7i.vogel.de/wcms/56/ec/56ecda05b645f0174c02631d95ca9aa4/0128668888v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/e2/dc/e2dc8cc128d8291e54f37ca35e8248e5/0128664847v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/b7/1f/b71f799b120d23d0e02ebd842b8f283d/0128664826v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/d3/e6/d3e627e1a7a3499dee3963b2d92b436e/0128662433v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/da/7b/da7bec8afb1d52df543beeae45d72a7d/0128897637v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/63/76/6376fa62330fa0d7d1b2894f2846f178/0128642999v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/b3/c8/b3c896b2ce5fe0a96ed752fb1de584b3/0128639452v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/45/5a/455abbe9e9c1c2f675e6894d9e099247/0128640705v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/2c/87/2c879e9ba1bd966c7003802f0b8e1149/0128880738v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/f2/d4/f2d42a2b7ad97329aeafb49c514f63f3/0128879848v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/94/f2/94f2a278fd90b0da7400966874f44950/0128605000v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/1f/52/1f528d0628ffe679a69a2e9f65c0e157/0128668896v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/51/7a/517a4e83c5827663b4839f5ddb98f434/0128872953v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/6b/76/6b7630a6787b986539ec5cd63bd20309/0128851233v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/ca/ae/caaeba5fe175e8897b288263ea6eb6d3/0128662705v3.jpeg)

:quality(80)/p7i.vogel.de/wcms/f9/c9/f9c98fb1ce8fd419a727d7ec2d002bb2/0128639430v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/be/e1/bee13b8d51a419b9b8f0685e2b9d47bf/0128917673v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/d5/72/d5728578b35b72f365f5086bc1d068da/0128662441v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/a9/69/a96920e47e362a9cf0b9916b7ad3d30a/0128071795v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/3b/fd/3bfda4bbcb1a60004c330bde3b705109/0128453300v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/cc/19/cc19aa5fec6f6f2b25dbd9516efed735/0128077403v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/de/66/de66dd32e1af2fa37ff20bded4417afc/0127787418v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/d5/78/d578d9a15e78a46fad46847d963a04c2/0127547393v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/6b/cc/6bcc3d26e1c7c74d90a10bc3ca296ae1/0128362351v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/24/c8/24c84ab6b1bcd24468a87820a07a85aa/0128194707v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/1d/3e/1d3e2788eb37c1e974f36337c8d33cb5/0128191010v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/19/76/1976928d7d0a2ed7c1eeba7ade8552c8/0126365603v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/89/8e/898eadf3c417034960d4afb39507d332/0128898269v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/c3/36/c336be5ddcc860374b32bd808d0bbd60/0128897614v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/55/a6/55a603fe7b33bd97422112947873961e/0128880375v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/ea/31/ea314f50f63f0dac76391f34d0d1b9c8/0128852176v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/f8/29/f8298429c1638b949a6f76346f6709c7/0118701710v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/07/24/07242664ab2b1c7841c9d9d0a127670c/0116045959.jpeg)

:quality(80)/p7i.vogel.de/wcms/c9/79/c979a20b32395ddfa93fe7ead90578a0/0108386061.jpeg)

:quality(80)/p7i.vogel.de/wcms/9e/5c/9e5c92d942ed046a27562d6e3d730c92/0103483548.jpeg)

:quality(80)/p7i.vogel.de/wcms/16/3d/163da381529db3a47348a9440655529b/0125732969v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/e7/82/e782bbbf96e4971c22241d76e5de1720/0124855387v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/f9/40/f940b2630f4805f08212fd851af46d6d/0124788233v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/3a/6d/3a6d046cf1db266c3009cecb2af8e2b7/0124656182v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/a8/4e/a84e8039a90a5cf4751d01ebcf6ba1a9/0127510172v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/17/c7/17c703445f134eb3d7ecc7918dda2762/0124596096v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/2a/2c/2a2cffc07f51019065387cd63241b5ce/0119463370v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/b1/7e/b17ea8c62ccafad1d1fb072d6199bbd6/0118578446.jpeg)

:quality(80)/p7i.vogel.de/wcms/a3/f6/a3f6cf659bef4a255272c8af711c20af/0128599957v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/d7/b4/d7b4415fef8a0be11c7f8fd4197edc92/0128599865v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/74/f0/74f0985278cb1fc0e4c79113ecb547e9/0128454101v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/6c/f5/6cf5218b7461e4607c0fd96c16b6fc93/0128454066v2.jpeg)

:fill(fff,0)/images.vogel.de/vogelonline/companyimg/2000/2093/65.jpg)

:fill(fff,0)/p7i.vogel.de/companies/61/f1/61f139b3bc666/ap-rgb-pos.png)

:fill(fff,0)/p7i.vogel.de/companies/68/c8/68c815bc8fe81/prominent-logo-300x300.jpeg)

:quality(80)/p7i.vogel.de/wcms/de/56/de567a18d20b770efccb05d472c45a62/0127607608v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/41/85/41850761720b85d6be9d51332da2b515/0125589239v2.jpeg)