Related Vendors

In 2003, Flow Tack, LLC, was formed as an engineering consulting company providing CFD and EFD services as a design tool for APC technologies including SCR, Static Mixers, Electro-Static Precipitators (ESP), Baghouses, and Flue Gas Desulphurization (FGD) units. The conventional apparatus for fluid dynamics optimization of the APC technology was EFD (example, Figure 2).

By the use of this method, Flow Tack engineers found that the experimental modeling suffered from the following drawbacks and limitations. With experimental models one does not have access to the full continuum of flow field data and the engineering analysis is limited to the finite number of points at which measurements are taken. There is always the paradox of locating discrete measurement points that are required to best capture potential problem areas which are not a priori known.

CFD: The Crucial Factors for Early Adopters

On top of that, there is the need for highly–skilled experimentalists to gather and apply data. Lastly, the time required to test, then modify, and then retest experimental models becomes a significant limiting factor in the degree of system optimization when complying with typical project schedules.

:quality(80)/images.vogel.de/vogelonline/bdb/886200/886208/original.jpg)

Retainer Systems

Fighting Air Pollution: Tracking and Retaining Particulate Matter

For these reasons, Flow Tack was an early adopter of CFD and helped promote the use of this revolutionary tool in the APC marketplace. Among other benefits, CFD made it possible to look at the entire continuum of flow vectors. By looking at the continuum, Flow Tack engineers noticed recirculation being caused by typical SCR flow distribution devices that were not always evident in experimental models. It became obvious that such flow conditions were the cause of many particulate related SCR problems.

Optimising Plant Performance

CFD also made it inexpensive to try many different flow distribution device configurations in order to optimize the velocity profiles entering the catalyst, and thus reduce the potential for ash accumulations.

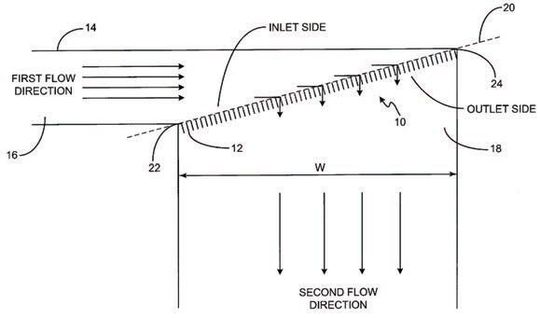

As shown in Figure 3, the GSG design was aimed to minimize horizontal surfaces predisposed to ash build-up in order to provide a much denser grid of plates, resulting in a more uniformly distributed resistance and consequently, a better velocity profile into the catalyst.

(ID:43684515)

:quality(80)/p7i.vogel.de/wcms/56/ec/56ecda05b645f0174c02631d95ca9aa4/0128668888v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/e2/dc/e2dc8cc128d8291e54f37ca35e8248e5/0128664847v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/b7/1f/b71f799b120d23d0e02ebd842b8f283d/0128664826v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/d3/e6/d3e627e1a7a3499dee3963b2d92b436e/0128662433v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/da/7b/da7bec8afb1d52df543beeae45d72a7d/0128897637v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/63/76/6376fa62330fa0d7d1b2894f2846f178/0128642999v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/b3/c8/b3c896b2ce5fe0a96ed752fb1de584b3/0128639452v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/45/5a/455abbe9e9c1c2f675e6894d9e099247/0128640705v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/2c/87/2c879e9ba1bd966c7003802f0b8e1149/0128880738v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/f2/d4/f2d42a2b7ad97329aeafb49c514f63f3/0128879848v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/94/f2/94f2a278fd90b0da7400966874f44950/0128605000v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/1f/52/1f528d0628ffe679a69a2e9f65c0e157/0128668896v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/51/7a/517a4e83c5827663b4839f5ddb98f434/0128872953v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/6b/76/6b7630a6787b986539ec5cd63bd20309/0128851233v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/ca/ae/caaeba5fe175e8897b288263ea6eb6d3/0128662705v3.jpeg)

:quality(80)/p7i.vogel.de/wcms/f9/c9/f9c98fb1ce8fd419a727d7ec2d002bb2/0128639430v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/be/e1/bee13b8d51a419b9b8f0685e2b9d47bf/0128917673v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/d5/72/d5728578b35b72f365f5086bc1d068da/0128662441v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/a9/69/a96920e47e362a9cf0b9916b7ad3d30a/0128071795v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/3b/fd/3bfda4bbcb1a60004c330bde3b705109/0128453300v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/cc/19/cc19aa5fec6f6f2b25dbd9516efed735/0128077403v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/de/66/de66dd32e1af2fa37ff20bded4417afc/0127787418v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/d5/78/d578d9a15e78a46fad46847d963a04c2/0127547393v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/6b/cc/6bcc3d26e1c7c74d90a10bc3ca296ae1/0128362351v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/24/c8/24c84ab6b1bcd24468a87820a07a85aa/0128194707v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/1d/3e/1d3e2788eb37c1e974f36337c8d33cb5/0128191010v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/19/76/1976928d7d0a2ed7c1eeba7ade8552c8/0126365603v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/89/8e/898eadf3c417034960d4afb39507d332/0128898269v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/c3/36/c336be5ddcc860374b32bd808d0bbd60/0128897614v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/55/a6/55a603fe7b33bd97422112947873961e/0128880375v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/ea/31/ea314f50f63f0dac76391f34d0d1b9c8/0128852176v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/f8/29/f8298429c1638b949a6f76346f6709c7/0118701710v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/07/24/07242664ab2b1c7841c9d9d0a127670c/0116045959.jpeg)

:quality(80)/p7i.vogel.de/wcms/c9/79/c979a20b32395ddfa93fe7ead90578a0/0108386061.jpeg)

:quality(80)/p7i.vogel.de/wcms/9e/5c/9e5c92d942ed046a27562d6e3d730c92/0103483548.jpeg)

:quality(80)/p7i.vogel.de/wcms/16/3d/163da381529db3a47348a9440655529b/0125732969v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/e7/82/e782bbbf96e4971c22241d76e5de1720/0124855387v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/f9/40/f940b2630f4805f08212fd851af46d6d/0124788233v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/3a/6d/3a6d046cf1db266c3009cecb2af8e2b7/0124656182v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/a8/4e/a84e8039a90a5cf4751d01ebcf6ba1a9/0127510172v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/17/c7/17c703445f134eb3d7ecc7918dda2762/0124596096v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/2a/2c/2a2cffc07f51019065387cd63241b5ce/0119463370v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/b1/7e/b17ea8c62ccafad1d1fb072d6199bbd6/0118578446.jpeg)

:quality(80)/p7i.vogel.de/wcms/a3/f6/a3f6cf659bef4a255272c8af711c20af/0128599957v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/d7/b4/d7b4415fef8a0be11c7f8fd4197edc92/0128599865v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/74/f0/74f0985278cb1fc0e4c79113ecb547e9/0128454101v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/6c/f5/6cf5218b7461e4607c0fd96c16b6fc93/0128454066v2.jpeg)

:fill(fff,0)/images.vogel.de/vogelonline/companyimg/2000/2093/65.jpg)

:fill(fff,0)/p7i.vogel.de/companies/61/f1/61f139b3bc666/ap-rgb-pos.png)

:fill(fff,0)/p7i.vogel.de/companies/68/c8/68c815bc8fe81/prominent-logo-300x300.jpeg)

:quality(80)/p7i.vogel.de/wcms/de/56/de567a18d20b770efccb05d472c45a62/0127607608v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/41/85/41850761720b85d6be9d51332da2b515/0125589239v2.jpeg)