Related Vendors

The Cryogenic Process – a System Example

After the plastic granules have been metered out of the silo, the coarse material from the screening machine is added and this mixture is then fed to the whirling motion screw cooler, the granules are conveyed to the Contraplex pin mill CW (or the fine impact mill UPZ) and are ground. The product is discharged via a silo-mounted filter to the downstream screening machine, where the fine product is screened and discharged as end-product via an automatic filter. The coarse fraction of the screening machine is conveyed back to the cryogenic feeder for recirculation.

A Cryogenic Process — Listing all Aspects of the System

An automatic cryogenic control unit controls the supply of the LN2 to the entire system. The system is insulated to minimize the consumption of nitrogen. All-important process parameters, e.g., mill speed, power consumption, throughput rate and nitrogen consumption are measured and evaluated.

A Practical and Economical solution for Viscoelastic Materials

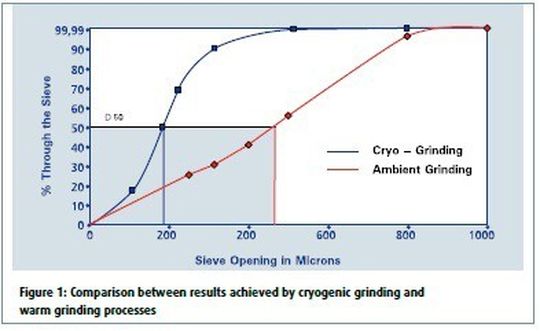

In view of the fact that the cost of raw materials and energy is increasing day by day, it is important to optimize the capacity and at the same time achieve the required quality. The cryogenic grinding process provides extremely high particle fineness values along with high product quality. Cooling the grinding process with liquid nitrogen prevents the temperatures of plastics from rising above the softening point. This rules out product melting and the subsequent formation of build-up, and additionally enhances the particle shape and thus the flow property of the fine powder.

These aspects constitute the significant advantages of cryogenic grinding compared with conventional grinding and furthermore add value to the product.

:quality(80)/images.vogel.de/vogelonline/bdb/407200/407268/original.jpg)

Mixer Cleaning

How to Optimize Dry Cleaning Methods for Bulk Residues in Mixers

* The author is Operations Director- Chemicals Division, HOSOKAWA ALPINE Aktiengesellschaft

(ID:42757651)

:quality(80)/p7i.vogel.de/wcms/60/25/60259e0165560492b717049a5006b5d2/0129719891v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/40/8f/408f074f8094bca2cd9bb078e79eccb0/0129580192v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/f3/4a/f34abcf99d71d8bff5a4e98b60889c8e/0129239597v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/5c/27/5c27bddaef122b61c636e31d82a33bd9/0129017834v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/3f/e3/3fe39c03ebb8bb0d4b4f46099ebd99e4/0129746348v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/cc/2a/cc2adab5b0d9dfe126364d289a5f16f1/0129688606v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/0a/1c/0a1c5f661e1df4b35d4cd8e4901e4035/0129624833v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/9f/7f/9f7f9d5256b75ba8141a63bbf981b793/0129506442v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/74/af/74af2b65341eeee13a44bc85eb759596/0129839901v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/26/12/261210e5920899e5c35c4f905d3be8bd/0129399814v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/d7/9e/d79e4ba6b9e0923d1513b843962712d9/0129591121v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/3e/e6/3ee6ff7ac2852491ce36fd6cb84bb7f0/0129534719v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/42/67/42671f576c7f8a1284b54bc8f92cce02/0129864175v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/f7/70/f770417abff565b1743068fa37d21266/0129833262v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/9f/7c/9f7cd6c9dcb679827c4c2c10f116c8b9/0129832882v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/91/d3/91d363e4abe71708f00b7205b2d32eff/0129746143v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/be/e1/bee13b8d51a419b9b8f0685e2b9d47bf/0128917673v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/51/7a/517a4e83c5827663b4839f5ddb98f434/0128872953v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/d5/72/d5728578b35b72f365f5086bc1d068da/0128662441v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/a9/69/a96920e47e362a9cf0b9916b7ad3d30a/0128071795v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/c4/54/c454c7d8fd344c0ffc2ef5db00ad632f/0129728429v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/18/47/1847e6b1456c96f04bd511bbd21f3779/0129039479v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/3b/fd/3bfda4bbcb1a60004c330bde3b705109/0128453300v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/cc/19/cc19aa5fec6f6f2b25dbd9516efed735/0128077403v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/6b/cc/6bcc3d26e1c7c74d90a10bc3ca296ae1/0128362351v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/24/c8/24c84ab6b1bcd24468a87820a07a85aa/0128194707v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/1d/3e/1d3e2788eb37c1e974f36337c8d33cb5/0128191010v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/19/76/1976928d7d0a2ed7c1eeba7ade8552c8/0126365603v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/2b/ec/2bec59da942498af975ef5a8835f9452/0129863223v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/e5/ad/e5ad680643cf15b1d1282231c3dc0989/0129832856v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/e7/cc/e7cc48a384ef2e790f79f1de7f54597b/0129729765v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/f8/29/f8298429c1638b949a6f76346f6709c7/0118701710v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/07/24/07242664ab2b1c7841c9d9d0a127670c/0116045959.jpeg)

:quality(80)/p7i.vogel.de/wcms/c9/79/c979a20b32395ddfa93fe7ead90578a0/0108386061.jpeg)

:quality(80)/p7i.vogel.de/wcms/9e/5c/9e5c92d942ed046a27562d6e3d730c92/0103483548.jpeg)

:quality(80)/p7i.vogel.de/wcms/16/3d/163da381529db3a47348a9440655529b/0125732969v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/e7/82/e782bbbf96e4971c22241d76e5de1720/0124855387v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/f9/40/f940b2630f4805f08212fd851af46d6d/0124788233v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/3a/6d/3a6d046cf1db266c3009cecb2af8e2b7/0124656182v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/a8/4e/a84e8039a90a5cf4751d01ebcf6ba1a9/0127510172v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/17/c7/17c703445f134eb3d7ecc7918dda2762/0124596096v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/2a/2c/2a2cffc07f51019065387cd63241b5ce/0119463370v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/b1/7e/b17ea8c62ccafad1d1fb072d6199bbd6/0118578446.jpeg)

:quality(80)/p7i.vogel.de/wcms/01/9b/019b59f3ef2e852ec5058ba18f323af2/0129651573v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/99/d2/99d2e5e83062b4cf2aa3dc0a60d15f23/0129624804v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/d1/a8/d1a83b822e16733380268322d033abdc/0129239584v2.jpeg)

:fill(fff,0)/images.vogel.de/vogelonline/companyimg/2000/2093/65.jpg)

:fill(fff,0)/images.vogel.de/vogelonline/companyimg/101800/101879/65.jpg)

:fill(fff,0)/images.vogel.de/vogelonline/companyimg/64500/64561/65.jpg)

:quality(80)/p7i.vogel.de/wcms/fe/98/fe98af24913a7f122606374ff2467dc8/0125888891v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/41/85/41850761720b85d6be9d51332da2b515/0125589239v2.jpeg)