Related Vendors

The key to the Dream Reaction is a revolutionary catalyst which enables the integration of CO2 molecules along with Propylene oxide (PO) directly in the hydrocarbon chain. “To ensure that both substances react in the stirred boiler, extra high pressure and temperatures are necessary”, says Project Manager Dr. Carsten Malsch.

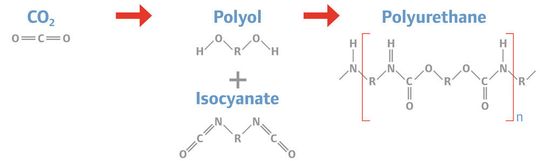

CO2 still exists in gaseous form at room temperature while PO boils at 34 °C. Once the reaction is in progress, the binding energy of the Propylene oxide is sufficient for a continuation, explained the developers – there is no need to feed additional heat. We have one CO2 molecule in the centre of three PO molecules – approx. 20% by weight. The poly-oil is finally used with Isocyanate for foam production.

In this context, the following rule is applicable: Long chain poly-oils yield softer polyurethanes. Good to know because the newly developed molecule is ideal for smooth PUR production, but yields stiffer forms of foam with petrochemical raw materials. As approximately two thirds of a PUR consists of poly-oils, the finished plastic contains approx. 10% CO2.

Developing A Catalysts for CO" Utilisation

“The search for a suitable catalyst lasted 40 years. That we have found it is attributable most of all to the collaboration with RWTH Aachen”, recollects Dr. Malsch. At the CAT Catalytic Center – a research institution run jointly with RWTH – the developers put their heads together. Rector Prof. Dr. Ernst Schmachtenberg also remembers the herculean task: “Using CO2 in an efficient way chemically, is a scientific challenge. We made a breakthrough in the interaction between application-oriented basic research and research-based industry.”

Catalysts on the basis of transition metals like Cobalt, Zinc, Chromium or Aluminium were tested for their suitability for polymerization with CO2. As the plastics industry requires long-chain hydrocarbons, it was necessary to avoid the occurrence of cyclical connections. ZnCl2 catalysts in particular were very convincing in the matter of selectivity and economy.

The Role of Research and Development

“Research must address global questions and be able to answer them”, Prof. Schmachtenberg is confident. The scientist sees in the Dream Production project the opportunity of detaching the CO2 economy from the vicious circle of fossil raw materials and climate-damaging emissions: “Not only does Germany have the opportunity to show how the energy threshold works, it can also illustrate how a carbon cycle economy is possible!”

(ID:44191641)

:quality(80)/p7i.vogel.de/wcms/60/25/60259e0165560492b717049a5006b5d2/0129719891v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/40/8f/408f074f8094bca2cd9bb078e79eccb0/0129580192v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/f3/4a/f34abcf99d71d8bff5a4e98b60889c8e/0129239597v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/5c/27/5c27bddaef122b61c636e31d82a33bd9/0129017834v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/3f/e3/3fe39c03ebb8bb0d4b4f46099ebd99e4/0129746348v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/cc/2a/cc2adab5b0d9dfe126364d289a5f16f1/0129688606v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/0a/1c/0a1c5f661e1df4b35d4cd8e4901e4035/0129624833v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/9f/7f/9f7f9d5256b75ba8141a63bbf981b793/0129506442v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/26/12/261210e5920899e5c35c4f905d3be8bd/0129399814v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/d7/9e/d79e4ba6b9e0923d1513b843962712d9/0129591121v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/3e/e6/3ee6ff7ac2852491ce36fd6cb84bb7f0/0129534719v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/fc/42/fc420e2134a13a67212be7e5f68c63d6/0129419035v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/91/d3/91d363e4abe71708f00b7205b2d32eff/0129746143v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/30/65/3065b16f11e1f1bbbb6fad217b735696/0129728979v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/27/76/277629e55f32cc82a35719ecb903496a/0129687208v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/01/9b/019b59f3ef2e852ec5058ba18f323af2/0129651573v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/be/e1/bee13b8d51a419b9b8f0685e2b9d47bf/0128917673v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/51/7a/517a4e83c5827663b4839f5ddb98f434/0128872953v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/d5/72/d5728578b35b72f365f5086bc1d068da/0128662441v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/a9/69/a96920e47e362a9cf0b9916b7ad3d30a/0128071795v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/c4/54/c454c7d8fd344c0ffc2ef5db00ad632f/0129728429v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/18/47/1847e6b1456c96f04bd511bbd21f3779/0129039479v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/3b/fd/3bfda4bbcb1a60004c330bde3b705109/0128453300v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/cc/19/cc19aa5fec6f6f2b25dbd9516efed735/0128077403v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/6b/cc/6bcc3d26e1c7c74d90a10bc3ca296ae1/0128362351v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/24/c8/24c84ab6b1bcd24468a87820a07a85aa/0128194707v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/1d/3e/1d3e2788eb37c1e974f36337c8d33cb5/0128191010v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/19/76/1976928d7d0a2ed7c1eeba7ade8552c8/0126365603v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/e7/cc/e7cc48a384ef2e790f79f1de7f54597b/0129729765v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/4a/80/4a8098395b0ced59ef40683f84ab30eb/0129685918v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/fc/c4/fcc4af0d5d9a0ebe17305f4983a2c2f1/0129668183v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/e4/a1/e4a1f8a6d645cb9b0c758f2bc89f3e22/0129667956v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/f8/29/f8298429c1638b949a6f76346f6709c7/0118701710v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/07/24/07242664ab2b1c7841c9d9d0a127670c/0116045959.jpeg)

:quality(80)/p7i.vogel.de/wcms/c9/79/c979a20b32395ddfa93fe7ead90578a0/0108386061.jpeg)

:quality(80)/p7i.vogel.de/wcms/9e/5c/9e5c92d942ed046a27562d6e3d730c92/0103483548.jpeg)

:quality(80)/p7i.vogel.de/wcms/16/3d/163da381529db3a47348a9440655529b/0125732969v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/e7/82/e782bbbf96e4971c22241d76e5de1720/0124855387v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/f9/40/f940b2630f4805f08212fd851af46d6d/0124788233v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/3a/6d/3a6d046cf1db266c3009cecb2af8e2b7/0124656182v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/a8/4e/a84e8039a90a5cf4751d01ebcf6ba1a9/0127510172v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/17/c7/17c703445f134eb3d7ecc7918dda2762/0124596096v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/2a/2c/2a2cffc07f51019065387cd63241b5ce/0119463370v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/b1/7e/b17ea8c62ccafad1d1fb072d6199bbd6/0118578446.jpeg)

:quality(80)/p7i.vogel.de/wcms/99/d2/99d2e5e83062b4cf2aa3dc0a60d15f23/0129624804v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/d1/a8/d1a83b822e16733380268322d033abdc/0129239584v2.jpeg)

:fill(fff,0)/p7i.vogel.de/companies/68/07/6807ad98568ce/logo-elementar-rgb.jpeg)

:fill(fff,0)/images.vogel.de/vogelonline/companyimg/2000/2093/65.jpg)

:fill(fff,0)/p7i.vogel.de/companies/61/f9/61f9439b7cbe4/logo-edl.png)

:quality(80)/p7i.vogel.de/wcms/c8/b1/c8b1d42480b31c8048984d7349245a24/0128406704v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/37/4d/374d774c546ba8c58990890c85860fed/0123745205v2.jpeg)