Related Vendors

In all, 36 companies in Europe are vying to take a piece of smaller and smaller cake – 70 % are located in three major markets: Germany, the Benelux states and France. Chlorine is produced where it is consumed. Production is often distributed and small-scale. Is this fragmented market structure viable in today’s world?

The Mercury Problem

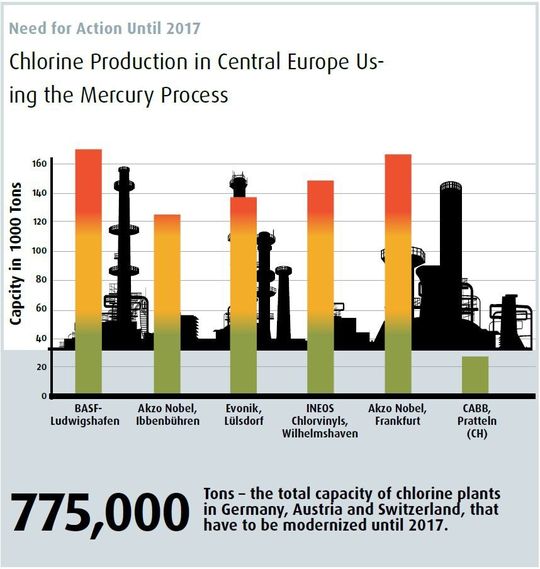

On top of all that, the EU is now getting involved: Earlier than expected, the conventional production method using the so called amalgam process is to be phased out in Europe. Plants which use the toxic transition metal may continue operating until 2017, but not after that. Membrane electrolysis is an alternative, but 22% of European chlorine production still uses mercury.

The conversion of existing mercury based chlorine production sites is, nevertheless, not without difficulties: If one simply converts an existing site, keeping as much assets as possible, additional process steps have to be added. Reusing an existing brine system, for example, requires a save and continuous mercury removal process - yet, this continuity can help to significantly cut total investment costs. A possible solution for brine treatment could be the precipation with sodium sulfite (Na2S), followed by a filtration of the resulting HgS-solids.

Technology paving the Way

With new and modernized plant technology, Europe’s chorine producer were able to reduce mercury emissions to around 0.73 g per ton of chlorine produced (slighty less than the 0.81 g/t of 2011). Most of this average reduction of emissions is due to the improvement shown by the lower performing plants, Euro Chlor speakers explained.

:quality(80)/images.vogel.de/vogelonline/bdb/695200/695285/original.jpg)

Efficient Chlorine Production

Bayer: High Hopes for ODC Chlorine Production Technology

New technologies, like the NaCl-ODC electrolysis that was jointly developed by Thyssen Krupp, Uhdenora and Bayer Material Science can bring a significant reduction of energy consumption of up to 30% compared to conventional membrane-based technology. The main feature of this development is an oxygen-injection at the cathode which surpasses the formation of hydrogen. As a result, the cell voltage is reduced from about 3 V to 2 V, enabling a higher capacity or less energy consumption. Since the electrolysis cells and brine cycle are the same as with the conventional membrane process, both technologies can be combined in a single plant.

(ID:42706718)

:quality(80)/p7i.vogel.de/wcms/f3/4a/f34abcf99d71d8bff5a4e98b60889c8e/0129239597v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/5c/27/5c27bddaef122b61c636e31d82a33bd9/0129017834v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/f7/f0/f7f0fdf4a4e1d872d078d63abfa4a7fd/0127844838v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/1e/50/1e5099910c2370ad08d578161f3fe3c2/0128939735v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/ed/af/edaf3b0b2506f65f338232550b661eb3/0129281129v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/66/29/66293f3c9de08b472f095dc9602bcc7d/0129279548v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/5b/e1/5be15b3ec731f81589ae9b16a43ac54c/0129243604v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/40/6d/406de78846e840f6c7cf7849cbf0ab08/0129163370v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/2c/87/2c879e9ba1bd966c7003802f0b8e1149/0128880738v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/f2/d4/f2d42a2b7ad97329aeafb49c514f63f3/0128879848v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/94/f2/94f2a278fd90b0da7400966874f44950/0128605000v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/1f/52/1f528d0628ffe679a69a2e9f65c0e157/0128668896v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/8d/a1/8da1c8bc8ce0fc8270a280ab1908bfc7/0129389288v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/6f/c4/6fc4c90b3bf74992ead5f24e7593ccf1/0129320690v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/d0/1b/d01bf797fa89982391d0ac726c3d69aa/0129278531v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/03/11/031137c1a0c2b4407960a762fd0fd915/0129189201v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/be/e1/bee13b8d51a419b9b8f0685e2b9d47bf/0128917673v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/51/7a/517a4e83c5827663b4839f5ddb98f434/0128872953v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/d5/72/d5728578b35b72f365f5086bc1d068da/0128662441v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/a9/69/a96920e47e362a9cf0b9916b7ad3d30a/0128071795v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/18/47/1847e6b1456c96f04bd511bbd21f3779/0129039479v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/3b/fd/3bfda4bbcb1a60004c330bde3b705109/0128453300v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/cc/19/cc19aa5fec6f6f2b25dbd9516efed735/0128077403v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/de/66/de66dd32e1af2fa37ff20bded4417afc/0127787418v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/6b/cc/6bcc3d26e1c7c74d90a10bc3ca296ae1/0128362351v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/24/c8/24c84ab6b1bcd24468a87820a07a85aa/0128194707v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/1d/3e/1d3e2788eb37c1e974f36337c8d33cb5/0128191010v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/19/76/1976928d7d0a2ed7c1eeba7ade8552c8/0126365603v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/ce/57/ce57e2593263485e488b2414f289f06c/0129390574v4.jpeg)

:quality(80)/p7i.vogel.de/wcms/c9/c1/c9c131b824359a6c8c6397242453a541/0129390568v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/77/89/7789547fde08bdb4761412b2d36b60fa/0129356306v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/24/02/24020d915cea1699d8c1bb76fd4c3d1b/0129355928v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/f8/29/f8298429c1638b949a6f76346f6709c7/0118701710v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/07/24/07242664ab2b1c7841c9d9d0a127670c/0116045959.jpeg)

:quality(80)/p7i.vogel.de/wcms/c9/79/c979a20b32395ddfa93fe7ead90578a0/0108386061.jpeg)

:quality(80)/p7i.vogel.de/wcms/9e/5c/9e5c92d942ed046a27562d6e3d730c92/0103483548.jpeg)

:quality(80)/p7i.vogel.de/wcms/16/3d/163da381529db3a47348a9440655529b/0125732969v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/e7/82/e782bbbf96e4971c22241d76e5de1720/0124855387v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/f9/40/f940b2630f4805f08212fd851af46d6d/0124788233v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/3a/6d/3a6d046cf1db266c3009cecb2af8e2b7/0124656182v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/a8/4e/a84e8039a90a5cf4751d01ebcf6ba1a9/0127510172v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/17/c7/17c703445f134eb3d7ecc7918dda2762/0124596096v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/2a/2c/2a2cffc07f51019065387cd63241b5ce/0119463370v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/b1/7e/b17ea8c62ccafad1d1fb072d6199bbd6/0118578446.jpeg)

:quality(80)/p7i.vogel.de/wcms/d1/a8/d1a83b822e16733380268322d033abdc/0129239584v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/bb/54/bb54162539c6fc9ac135719af078ea06/0129188218v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/02/02/020250273eb250f46d355a16c1baeb74/0129163933v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/3f/69/3f69ed74aeaa46ac08dcd9fbe1f2d497/0129141343v2.jpeg)

:fill(fff,0)/images.vogel.de/vogelonline/companyimg/2000/2093/65.jpg)

:fill(fff,0)/images.vogel.de/vogelonline/companyimg/103000/103097/65.jpg)

:fill(fff,0)/p7i.vogel.de/companies/68/c8/68c815bc8fe81/prominent-logo-300x300.jpeg)

:quality(80)/p7i.vogel.de/wcms/de/9b/de9bf14c528bb0bc792ae8cb77931fa3/0125217925v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/9e/0a/9e0af66496a6a027db9b36b5c331a0e0/0125345648v2.jpeg)