World-First Technological Breakthrough Zirconia Powders: Redesigned Particle Structure Makes Low-Temperature Sintering Possible

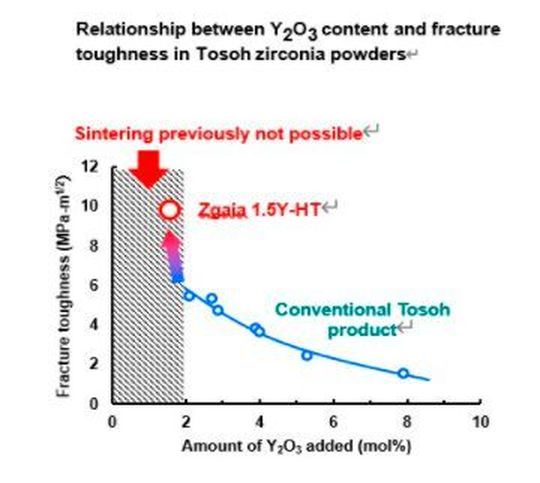

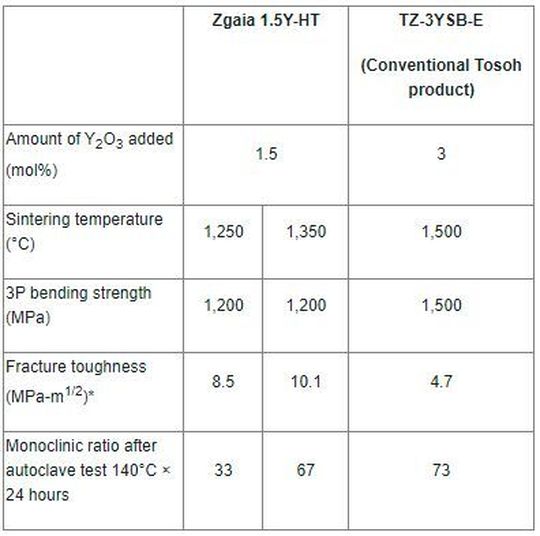

Tosoh Corporation has introduced its latest zirconia powder – the Zgaia series. Its unique features include a redesigned particle structure which makes low-temperature sintering possible at 1,250°C than the conventional 1,500°C, thus, reducing carbon dioxide emissions in the manufacturing process. Also, a yttrium oxide (Y2O3) content of only 1.5 mol % is sufficient for sintering Zgaia 1.5Y-HT.

Related Vendors

Tokyo/Japan – Tosoh Corporation has recently announced its newest addition to its line-up of zirconia powders, the Zgaia series. The company’s redesign of the particle structure of conventional zirconia makes possible lower-temperature sintering, at 1,250°C, than the usual 1,500°C, thus, reducing carbon dioxide emissions in the manufacturing process.

Tosoh’s Zgaia 1.5Y-HT is a world first. It features the lowest level of yttrium oxide (Y2O3) content, of only 1.5 mol %, ever achieved in zirconia, while exhibiting both superior bending strength and fracture toughness. Furthermore, Tosoh will also start introducing to customers the Zgaia series’ 3Y-LD grade, which features high durability owed to past efforts of Tosoh R&D.

The mechanism behind Zgaia 1.5Y-HT’s fracture toughness, meanwhile, is being investigated by the Next Generation Zirconia Social Cooperation Program, which involves the University of Tokyo and Tosoh Corporation and other private companies. The participants in this research program plan to issue a joint announcement soon to inform customers of that mechanism. The company is also considering starting the mass production of its Zgaia series in tandem with the announcements regarding the mechanism of Zgaia 1.5Y-HT’s fracture toughness.

1. Features of the Zgaia series overall

A) A redesigned particle structure makes possible low-temperature sintering.

B) A proprietary manufacturing method ensures uniform Y2O3 distribution.

- A Y2O3 content of 1.5 mol % is sufficient for sintering Zgaia 1.5Y-HT.

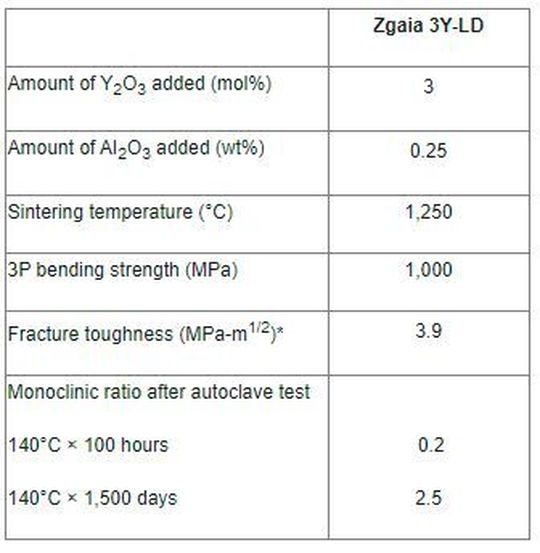

- A uniform microstructure of sintered particles suppresses hydrothermal degradation in Zgaia 3Y-LD.

2. Features of the Zgaia series by grade

A) Zgaia 1.5Y-HT

- A Y2O3 content lower than previously capable of being sintered enables the fracture toughness and bending strength not possible with conventional zirconia.

B) Zgaia 3Y-LD

- A four-year period of accelerated degradation tests where the sintered material was immersed in 140°C water resulted in almost no deterioration and confirmed Zgaia 3Y-LD’s remarkable durability.

(ID:47903815)

:quality(80)/p7i.vogel.de/wcms/5c/27/5c27bddaef122b61c636e31d82a33bd9/0129017834v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/f7/f0/f7f0fdf4a4e1d872d078d63abfa4a7fd/0127844838v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/1e/50/1e5099910c2370ad08d578161f3fe3c2/0128939735v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/56/ec/56ecda05b645f0174c02631d95ca9aa4/0128668888v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/e7/40/e74003abab999d9c5ff06672ed899136/0128971984v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/0b/c2/0bc2d35b3728c6155bcdc18aa0b4f43e/0128940631v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/ad/82/ad8217d5688276d9ed82b41be17e2edb/0128939746v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/fa/04/fa0408f795513d992edc5f098924e404/0128934009v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/2c/87/2c879e9ba1bd966c7003802f0b8e1149/0128880738v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/f2/d4/f2d42a2b7ad97329aeafb49c514f63f3/0128879848v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/94/f2/94f2a278fd90b0da7400966874f44950/0128605000v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/1f/52/1f528d0628ffe679a69a2e9f65c0e157/0128668896v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/56/c4/56c4f6ae76f9eec1eb35e53da62510c9/0129040644v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/cf/5b/cf5b66e0b2268fdadb5e20fd585edebb/0128971089v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/c1/67/c167f473ddeca77220259be63c52e80f/0128933152v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/be/e1/bee13b8d51a419b9b8f0685e2b9d47bf/0128917673v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/51/7a/517a4e83c5827663b4839f5ddb98f434/0128872953v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/d5/72/d5728578b35b72f365f5086bc1d068da/0128662441v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/a9/69/a96920e47e362a9cf0b9916b7ad3d30a/0128071795v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/18/47/1847e6b1456c96f04bd511bbd21f3779/0129039479v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/3b/fd/3bfda4bbcb1a60004c330bde3b705109/0128453300v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/cc/19/cc19aa5fec6f6f2b25dbd9516efed735/0128077403v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/de/66/de66dd32e1af2fa37ff20bded4417afc/0127787418v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/6b/cc/6bcc3d26e1c7c74d90a10bc3ca296ae1/0128362351v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/24/c8/24c84ab6b1bcd24468a87820a07a85aa/0128194707v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/1d/3e/1d3e2788eb37c1e974f36337c8d33cb5/0128191010v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/19/76/1976928d7d0a2ed7c1eeba7ade8552c8/0126365603v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/13/b0/13b07825931b39999b48634ea96f7bfb/0129040257v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/d8/26/d826876f8d4e1cb9be238005f31da84a/0129019696v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/9b/19/9b191cc35990bcfae941dcc78e49016e/0129018835v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/d4/ba/d4ba61e95ad0cdd0e150bb37d0f93afe/0128971702v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/f8/29/f8298429c1638b949a6f76346f6709c7/0118701710v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/07/24/07242664ab2b1c7841c9d9d0a127670c/0116045959.jpeg)

:quality(80)/p7i.vogel.de/wcms/c9/79/c979a20b32395ddfa93fe7ead90578a0/0108386061.jpeg)

:quality(80)/p7i.vogel.de/wcms/9e/5c/9e5c92d942ed046a27562d6e3d730c92/0103483548.jpeg)

:quality(80)/p7i.vogel.de/wcms/16/3d/163da381529db3a47348a9440655529b/0125732969v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/e7/82/e782bbbf96e4971c22241d76e5de1720/0124855387v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/f9/40/f940b2630f4805f08212fd851af46d6d/0124788233v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/3a/6d/3a6d046cf1db266c3009cecb2af8e2b7/0124656182v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/a8/4e/a84e8039a90a5cf4751d01ebcf6ba1a9/0127510172v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/17/c7/17c703445f134eb3d7ecc7918dda2762/0124596096v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/2a/2c/2a2cffc07f51019065387cd63241b5ce/0119463370v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/b1/7e/b17ea8c62ccafad1d1fb072d6199bbd6/0118578446.jpeg)

:quality(80)/p7i.vogel.de/wcms/a3/f6/a3f6cf659bef4a255272c8af711c20af/0128599957v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/d7/b4/d7b4415fef8a0be11c7f8fd4197edc92/0128599865v2.jpeg)

:fill(fff,0)/images.vogel.de/vogelonline/companyimg/2000/2093/65.jpg)

:fill(fff,0)/images.vogel.de/vogelonline/companyimg/101800/101879/65.jpg)

:fill(fff,0)/p7i.vogel.de/companies/5f/98/5f98fbb2e7bf2/05-trm-filter-logo-with-slogan-en-alt.png)

:quality(80)/p7i.vogel.de/wcms/cf/5b/cf5b66e0b2268fdadb5e20fd585edebb/0128971089v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/94/79/9479108d528aaad1ecabba3d23b6c6f8/0127622135v2.jpeg)