Related Vendors

“One Alloy Fits All” Might Not Be a Good Idea

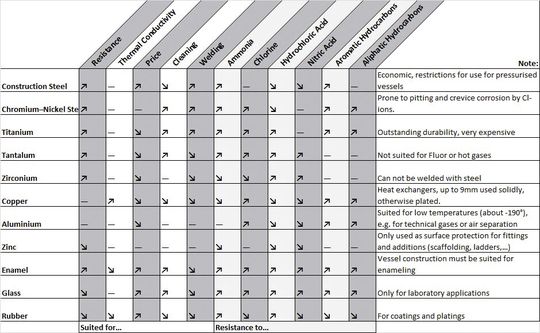

Good formability is a property which all types of stainless steel have in common. Equipment, vessels, interior components and tubing made of these alloys can be easily produced by rolling, forging or hammering. Stainless steel threading, nevertheless, is highly susceptible to seizure and that can easily cause problems on heated flanges, but advantages such as durability and cleanability offset that drawback. Despite the fact that they are relatively expensive, chromium and nickel alloy stainless steel are widely used in the equipment manufacturing, pharmaceutical and food processing industries. Chloride ions present in reactions where hydrochloric acid is involved are the only risk factor, as they can readily cause pitting and stress corrosion cracking.

But steel is not the only option. Other metals and alloys are commonly used in equipment manufacturing. Despite their high price tag (a thousand times more expensive than cast steel and 35 times more expensive than stainless steel), metals such as titanium and titanium alloys are often used because of their outstanding chemical resistance and relatively good workability.

Titanium, Tantalum and Co. - Special Metals and Alloys

Titanium alloys are a viable solution when stainless steel is not an option, especially when the media contain chloride. Titanium is the solution of choice for chlorine, urea and acetic acid production and for seawater desalination.

Tantalum is highly resistant to the corrosive effects of acids and alkalis but it is highly susceptible to attack by hot gas because it reacts with oxygen or steam at high temperatures. Zirconium is ideally suited for handling nitric acid but has high susceptibility to other acids.

(ID:42321285)

:quality(80)/p7i.vogel.de/wcms/f3/4a/f34abcf99d71d8bff5a4e98b60889c8e/0129239597v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/5c/27/5c27bddaef122b61c636e31d82a33bd9/0129017834v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/f7/f0/f7f0fdf4a4e1d872d078d63abfa4a7fd/0127844838v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/1e/50/1e5099910c2370ad08d578161f3fe3c2/0128939735v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/ed/af/edaf3b0b2506f65f338232550b661eb3/0129281129v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/66/29/66293f3c9de08b472f095dc9602bcc7d/0129279548v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/5b/e1/5be15b3ec731f81589ae9b16a43ac54c/0129243604v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/40/6d/406de78846e840f6c7cf7849cbf0ab08/0129163370v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/2c/87/2c879e9ba1bd966c7003802f0b8e1149/0128880738v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/f2/d4/f2d42a2b7ad97329aeafb49c514f63f3/0128879848v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/94/f2/94f2a278fd90b0da7400966874f44950/0128605000v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/1f/52/1f528d0628ffe679a69a2e9f65c0e157/0128668896v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/6f/c4/6fc4c90b3bf74992ead5f24e7593ccf1/0129320690v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/d0/1b/d01bf797fa89982391d0ac726c3d69aa/0129278531v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/03/11/031137c1a0c2b4407960a762fd0fd915/0129189201v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/47/4f/474fac12fca989a8d8db63de335dd78d/0129188583v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/be/e1/bee13b8d51a419b9b8f0685e2b9d47bf/0128917673v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/51/7a/517a4e83c5827663b4839f5ddb98f434/0128872953v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/d5/72/d5728578b35b72f365f5086bc1d068da/0128662441v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/a9/69/a96920e47e362a9cf0b9916b7ad3d30a/0128071795v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/18/47/1847e6b1456c96f04bd511bbd21f3779/0129039479v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/3b/fd/3bfda4bbcb1a60004c330bde3b705109/0128453300v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/cc/19/cc19aa5fec6f6f2b25dbd9516efed735/0128077403v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/de/66/de66dd32e1af2fa37ff20bded4417afc/0127787418v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/6b/cc/6bcc3d26e1c7c74d90a10bc3ca296ae1/0128362351v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/24/c8/24c84ab6b1bcd24468a87820a07a85aa/0128194707v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/1d/3e/1d3e2788eb37c1e974f36337c8d33cb5/0128191010v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/19/76/1976928d7d0a2ed7c1eeba7ade8552c8/0126365603v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/77/89/7789547fde08bdb4761412b2d36b60fa/0129356306v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/24/02/24020d915cea1699d8c1bb76fd4c3d1b/0129355928v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/71/dd/71ddfd1c5c3db0a0e7b4764c929b1a29/0129355907v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/53/5e/535e7f33b12b692072f51c4088f290fb/0129340389v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/f8/29/f8298429c1638b949a6f76346f6709c7/0118701710v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/07/24/07242664ab2b1c7841c9d9d0a127670c/0116045959.jpeg)

:quality(80)/p7i.vogel.de/wcms/c9/79/c979a20b32395ddfa93fe7ead90578a0/0108386061.jpeg)

:quality(80)/p7i.vogel.de/wcms/9e/5c/9e5c92d942ed046a27562d6e3d730c92/0103483548.jpeg)

:quality(80)/p7i.vogel.de/wcms/16/3d/163da381529db3a47348a9440655529b/0125732969v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/e7/82/e782bbbf96e4971c22241d76e5de1720/0124855387v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/f9/40/f940b2630f4805f08212fd851af46d6d/0124788233v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/3a/6d/3a6d046cf1db266c3009cecb2af8e2b7/0124656182v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/a8/4e/a84e8039a90a5cf4751d01ebcf6ba1a9/0127510172v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/17/c7/17c703445f134eb3d7ecc7918dda2762/0124596096v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/2a/2c/2a2cffc07f51019065387cd63241b5ce/0119463370v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/b1/7e/b17ea8c62ccafad1d1fb072d6199bbd6/0118578446.jpeg)

:quality(80)/p7i.vogel.de/wcms/d1/a8/d1a83b822e16733380268322d033abdc/0129239584v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/bb/54/bb54162539c6fc9ac135719af078ea06/0129188218v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/02/02/020250273eb250f46d355a16c1baeb74/0129163933v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/3f/69/3f69ed74aeaa46ac08dcd9fbe1f2d497/0129141343v2.jpeg)

:fill(fff,0)/images.vogel.de/vogelonline/companyimg/107800/107832/65.jpg)

:fill(fff,0)/images.vogel.de/vogelonline/companyimg/101800/101879/65.jpg)

:fill(fff,0)/images.vogel.de/vogelonline/companyimg/26900/26987/65.jpg)

:quality(80)/p7i.vogel.de/wcms/54/5f/545fd946d877e9ead377e5f33c959098/0127078441v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/83/cc/83cc4a0bbc4a973e742536edafe3ec8b/0125230620v2.jpeg)