Related Vendors

Defining the Parameters for Choosing a Valve

It also provides the flow coefficient (Cv)Vs valve handle turns chart that presents the amount of flow control obtained for a given number of valve handle turns, meaning how many turns of the handle will result in the corresponding flow. Since the setting of needle valves can not be determined from the position of the handle, it is necessary to know how to read this chart in order to decide only on the needle valves that falls within the specific needs.

If a user needs help with this information, top vendors are able to provide application or product engineering services intended to help navigate this information and make the most effective decision for product selection and implementation. When dealing with a quality vendor, it is recommended to consult with him prior to finalizing the needle-valve implementation. When a vendor is unable to provide this level of expertise consulting, it should be a first warning regarding the quality of the valves that are purchased from this vendor.

What to Consider for Panel Mounted Needle Valves

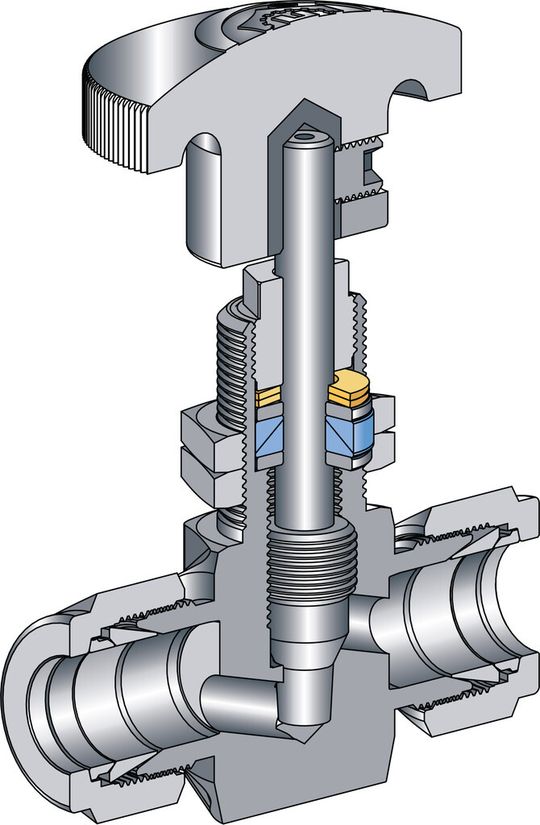

In many applications, a panel-mounted valve is required. Panel installation of a traditional needle-valve can be problematic, as it requires opening the valve assembly for the removal of the panel-nut to enable the valve’s bonnet mounting. Although seemingly simple, several aspects can cause problems with panel mounted designs:

- Opening the top packing-nut opens the actual packing sealing of the valve assembly and can invalidate manufacturer warranty. (The manufacturer cannot guarantee for proper valve closure by the user).

- Opening the top packing-nut may result in safety risk when the nut is not returned to its proper position and tightening torque.

- Therefore, for panel applications, it’s recommended to use one of the needle-valves higher quality configurations, which use a male nut that saves the need of valve opening for removal of the packing-nut. This configuration is shown on the previous page. It eliminates the safety and quality risk, and ensures that the needle-valve warranty is kept valid.

Sealing Methods for Leakage and Wear Prevention

Needle valves have a relatively high sealing material wear: During regular steady state operation as well as due to initiated changes of the handle position, the packing sealing material and valve undergo stress and abrasion. Ultimately, the related wear reduces the effective lifecycle of the valve, influencing the process overall costs: Each valve replacement contributes to the process’ bill, not only because of the valve price and replacement coasts but mainly due to the delays of the served industrial production. A relatively simple way to delay the replacement of a needle-valve for some time is to tighten the packing nut (about 1/8 turn each time) when a packing leakage is detected.

(ID:42501508)

:quality(80)/p7i.vogel.de/wcms/f3/4a/f34abcf99d71d8bff5a4e98b60889c8e/0129239597v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/5c/27/5c27bddaef122b61c636e31d82a33bd9/0129017834v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/f7/f0/f7f0fdf4a4e1d872d078d63abfa4a7fd/0127844838v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/1e/50/1e5099910c2370ad08d578161f3fe3c2/0128939735v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/ed/af/edaf3b0b2506f65f338232550b661eb3/0129281129v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/66/29/66293f3c9de08b472f095dc9602bcc7d/0129279548v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/5b/e1/5be15b3ec731f81589ae9b16a43ac54c/0129243604v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/40/6d/406de78846e840f6c7cf7849cbf0ab08/0129163370v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/2c/87/2c879e9ba1bd966c7003802f0b8e1149/0128880738v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/f2/d4/f2d42a2b7ad97329aeafb49c514f63f3/0128879848v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/94/f2/94f2a278fd90b0da7400966874f44950/0128605000v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/1f/52/1f528d0628ffe679a69a2e9f65c0e157/0128668896v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/69/08/6908c3bb3fba2484c5b541cb82c4e162/0129451354v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/d8/31/d831a92b2862f06b828503add415bd9a/0129449661v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/8d/a1/8da1c8bc8ce0fc8270a280ab1908bfc7/0129389288v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/6f/c4/6fc4c90b3bf74992ead5f24e7593ccf1/0129320690v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/be/e1/bee13b8d51a419b9b8f0685e2b9d47bf/0128917673v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/51/7a/517a4e83c5827663b4839f5ddb98f434/0128872953v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/d5/72/d5728578b35b72f365f5086bc1d068da/0128662441v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/a9/69/a96920e47e362a9cf0b9916b7ad3d30a/0128071795v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/18/47/1847e6b1456c96f04bd511bbd21f3779/0129039479v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/3b/fd/3bfda4bbcb1a60004c330bde3b705109/0128453300v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/cc/19/cc19aa5fec6f6f2b25dbd9516efed735/0128077403v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/de/66/de66dd32e1af2fa37ff20bded4417afc/0127787418v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/6b/cc/6bcc3d26e1c7c74d90a10bc3ca296ae1/0128362351v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/24/c8/24c84ab6b1bcd24468a87820a07a85aa/0128194707v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/1d/3e/1d3e2788eb37c1e974f36337c8d33cb5/0128191010v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/19/76/1976928d7d0a2ed7c1eeba7ade8552c8/0126365603v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/53/82/5382b72160f544c88671963328df1876/0129471274v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/9c/4c/9c4c1285656a01971aa4f3779002fde5/0129470303v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/ec/e4/ece471df12b2a2c5beae69c92a21730f/0129469695v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/ce/57/ce57e2593263485e488b2414f289f06c/0129390574v4.jpeg)

:quality(80)/p7i.vogel.de/wcms/f8/29/f8298429c1638b949a6f76346f6709c7/0118701710v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/07/24/07242664ab2b1c7841c9d9d0a127670c/0116045959.jpeg)

:quality(80)/p7i.vogel.de/wcms/c9/79/c979a20b32395ddfa93fe7ead90578a0/0108386061.jpeg)

:quality(80)/p7i.vogel.de/wcms/9e/5c/9e5c92d942ed046a27562d6e3d730c92/0103483548.jpeg)

:quality(80)/p7i.vogel.de/wcms/16/3d/163da381529db3a47348a9440655529b/0125732969v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/e7/82/e782bbbf96e4971c22241d76e5de1720/0124855387v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/f9/40/f940b2630f4805f08212fd851af46d6d/0124788233v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/3a/6d/3a6d046cf1db266c3009cecb2af8e2b7/0124656182v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/a8/4e/a84e8039a90a5cf4751d01ebcf6ba1a9/0127510172v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/17/c7/17c703445f134eb3d7ecc7918dda2762/0124596096v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/2a/2c/2a2cffc07f51019065387cd63241b5ce/0119463370v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/b1/7e/b17ea8c62ccafad1d1fb072d6199bbd6/0118578446.jpeg)

:quality(80)/p7i.vogel.de/wcms/d1/a8/d1a83b822e16733380268322d033abdc/0129239584v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/bb/54/bb54162539c6fc9ac135719af078ea06/0129188218v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/02/02/020250273eb250f46d355a16c1baeb74/0129163933v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/3f/69/3f69ed74aeaa46ac08dcd9fbe1f2d497/0129141343v2.jpeg)

:fill(fff,0)/images.vogel.de/vogelonline/companyimg/2000/2093/65.jpg)

:fill(fff,0)/images.vogel.de/vogelonline/companyimg/101800/101879/65.jpg)

:fill(fff,0)/images.vogel.de/vogelonline/companyimg/26900/26987/65.jpg)

:quality(80)/p7i.vogel.de/wcms/83/cc/83cc4a0bbc4a973e742536edafe3ec8b/0125230620v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/95/7d/957dc20162ca876b117e451622565deb/0126338596v2.jpeg)