Related Vendors

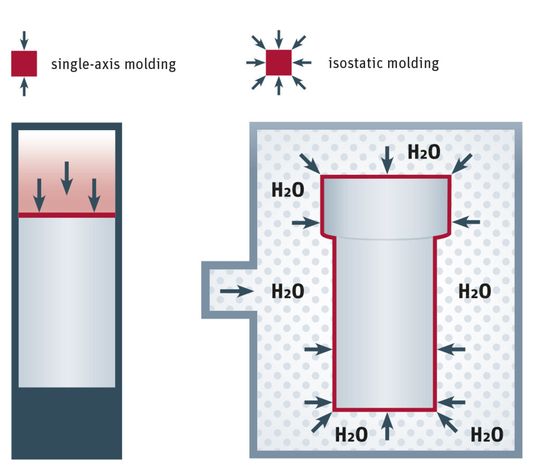

The process of isostatic compression moulding was developed by Berghof more than forty years ago in order to achieve optimal compression and excellent material properties. In the case of conventional, single-axis moulding the material is generally compressed vertically in a mould with a force plug. There is no horizontal compression crosswise to the direction of compression. With isostatic compression moulding on the other hand the force is applied to the material evenly and simultaneously from all directions via a hydraulic medium and uniformly compressed.

In this way optimal compression is achieved, resulting in minimal porosity, an improved surface structure and maximum tensile and compressive strength. No preferred directions are created and isotropic material properties are retained. In particular the tensile and compressive strength of the material is consistent in all spatial directions. Further processing of PTFE and TFM-PTFE by moulding follows the stages compression, sintering and cooling.

Quality Benefits of Perfluorinated PTFE

The advantages of isostatic compression moulding can be made clear by means of appropriately enlarged REM images. With the chain polymer a markedly finer and smoother structure is achieved. This results in a clear reduction in the risk of contamination and memory effects. Berghof microwave digestion systems are characterised by durable digestion vessels entirely manufactured of isostatically compressed polymer. Additional non-acid-resistant plastic materials are not used, guaranteeing simple and safe handling. The vessels consist of just a few components and can be opened and closed without the need for tools.

Digestion of Reference Materials in Mercury Checking

Mercury exhibits a large toxicological potential which explains the necessity for monitoring. In the past the applicability of vessels made of fluorplastics for wet chemical digestions has been controversial discussed. However, since a few years there is a greater readiness to accept such materials through modifications and improved properties. To investigate the memory effects in TFM-PTFE vessels the total mercury content of the following reference material was determined:

- Pine needles from the 15th Needle/Leaf Interlaboratory Test 2012/2013 of the Federal Research and Training Center for Forests, Natural Hazards and Landscapes, Vienna Mercury: 0.0338 ± 0.010 mg/kg

(ID:42501513)

:quality(80)/p7i.vogel.de/wcms/5c/27/5c27bddaef122b61c636e31d82a33bd9/0129017834v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/f7/f0/f7f0fdf4a4e1d872d078d63abfa4a7fd/0127844838v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/1e/50/1e5099910c2370ad08d578161f3fe3c2/0128939735v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/56/ec/56ecda05b645f0174c02631d95ca9aa4/0128668888v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/e7/40/e74003abab999d9c5ff06672ed899136/0128971984v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/0b/c2/0bc2d35b3728c6155bcdc18aa0b4f43e/0128940631v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/ad/82/ad8217d5688276d9ed82b41be17e2edb/0128939746v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/fa/04/fa0408f795513d992edc5f098924e404/0128934009v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/2c/87/2c879e9ba1bd966c7003802f0b8e1149/0128880738v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/f2/d4/f2d42a2b7ad97329aeafb49c514f63f3/0128879848v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/94/f2/94f2a278fd90b0da7400966874f44950/0128605000v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/1f/52/1f528d0628ffe679a69a2e9f65c0e157/0128668896v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/4d/18/4d188a46fc31c24e15b9c17d88aff0cd/0129071338v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/56/c4/56c4f6ae76f9eec1eb35e53da62510c9/0129040644v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/cf/5b/cf5b66e0b2268fdadb5e20fd585edebb/0128971089v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/be/e1/bee13b8d51a419b9b8f0685e2b9d47bf/0128917673v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/51/7a/517a4e83c5827663b4839f5ddb98f434/0128872953v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/d5/72/d5728578b35b72f365f5086bc1d068da/0128662441v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/a9/69/a96920e47e362a9cf0b9916b7ad3d30a/0128071795v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/18/47/1847e6b1456c96f04bd511bbd21f3779/0129039479v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/3b/fd/3bfda4bbcb1a60004c330bde3b705109/0128453300v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/cc/19/cc19aa5fec6f6f2b25dbd9516efed735/0128077403v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/de/66/de66dd32e1af2fa37ff20bded4417afc/0127787418v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/6b/cc/6bcc3d26e1c7c74d90a10bc3ca296ae1/0128362351v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/24/c8/24c84ab6b1bcd24468a87820a07a85aa/0128194707v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/1d/3e/1d3e2788eb37c1e974f36337c8d33cb5/0128191010v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/19/76/1976928d7d0a2ed7c1eeba7ade8552c8/0126365603v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/35/77/3577ece5e26778e0f023e978087a2c74/0129074947v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/b8/99/b899c0f88836053fc506864bc7edc31c/0129074306v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/13/b0/13b07825931b39999b48634ea96f7bfb/0129040257v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/d8/26/d826876f8d4e1cb9be238005f31da84a/0129019696v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/f8/29/f8298429c1638b949a6f76346f6709c7/0118701710v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/07/24/07242664ab2b1c7841c9d9d0a127670c/0116045959.jpeg)

:quality(80)/p7i.vogel.de/wcms/c9/79/c979a20b32395ddfa93fe7ead90578a0/0108386061.jpeg)

:quality(80)/p7i.vogel.de/wcms/9e/5c/9e5c92d942ed046a27562d6e3d730c92/0103483548.jpeg)

:quality(80)/p7i.vogel.de/wcms/16/3d/163da381529db3a47348a9440655529b/0125732969v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/e7/82/e782bbbf96e4971c22241d76e5de1720/0124855387v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/f9/40/f940b2630f4805f08212fd851af46d6d/0124788233v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/3a/6d/3a6d046cf1db266c3009cecb2af8e2b7/0124656182v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/a8/4e/a84e8039a90a5cf4751d01ebcf6ba1a9/0127510172v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/17/c7/17c703445f134eb3d7ecc7918dda2762/0124596096v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/2a/2c/2a2cffc07f51019065387cd63241b5ce/0119463370v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/b1/7e/b17ea8c62ccafad1d1fb072d6199bbd6/0118578446.jpeg)

:quality(80)/p7i.vogel.de/wcms/a3/f6/a3f6cf659bef4a255272c8af711c20af/0128599957v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/d7/b4/d7b4415fef8a0be11c7f8fd4197edc92/0128599865v2.jpeg)

:fill(fff,0)/p7i.vogel.de/companies/68/07/6807ad98568ce/logo-elementar-rgb.jpeg)

:fill(fff,0)/images.vogel.de/vogelonline/companyimg/2000/2093/65.jpg)

:fill(fff,0)/p7i.vogel.de/companies/67/f7/67f7b358f1b9f/ap-logo-cmyk-72dpi-jpg.jpeg)

:quality(80)/p7i.vogel.de/wcms/3a/d6/3ad65ecb7337a63b629428c256461943/0127773467v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/11/10/11101ac5360146f5f222aa3dd14788fe/0127051066v2.jpeg)